Levitra enthält Vardenafil, das eine kürzere Wirkdauer als Tadalafil hat, dafür aber schnell einsetzt. Männer, die diskret bestellen möchten, suchen häufig nach levitra kaufen ohne rezept. Dabei spielt die rechtliche Lage in der Schweiz eine wichtige Rolle.

Mouser.com

TAIYO YUDEN Lithium Ion Capacitors:

An Effective EDLC Replacement

Lithium Ion Capacitors overcome the pitfalls of EDLCs, providing

superior self-discharge characteristics, high-energy density,

reliability, longevity and safety.

Atsuya Sato Field Application Engineering Supervisor TAIYO YUDEN

TAIYO YUDEN Lithium Ion Capacitors:

The Ultimate EDLC Replacement

Background

An accepted energy solution, conventional Electrical Double Layer Capacitors (EDLC)

have many notable drawbacks relating to self-discharge characteristics, energy density,

reliability, longevity and thermal design. TAIYO YUDEN Lithium Ion Capacitors

overcome these issues and are an effective replacement for EDLCs. Lithium Ion Capacitors

are hybrid capacitors, featuring the best characteristics of both EDLC and Lithium Ion

Secondary Batteries (LIB).

EDLCs were first created in Japan in the 1970s and began appearing in various home appliances

in the 1990s. Since the 2000s, they have been used in mobile phones and digital cameras. EDLCs

are typically used to protect against sudden momentary drops or sudden interruptions in power.

They can instantaneously output large amounts of power, while a battery cannot. They are

frequently used as backup power sources in servers and storage devices for integrated circuits,

processors, memory and more.

While EDLCs are intended to be backup power sources, conventional EDLCs suffer from a

phenomenon known as self-discharge, where the capacitor will gradually lose its charge over

time. Self-discharge can occur more rapidly during exposure to high temperature environments.

The extremely low self-discharge of an Lithium Ion Capacitor, even in high heat

environments, ensures a long-lasting charge.

Furthermore, Lithium Ion Capacitors have no risk of thermal runaway. No additional

thermal design considerations, space or components are necessary when designing with an

Lithium Ion Capacitor.

The use of Lithium Ion Capacitors is steadily growing. They are increasingly relied on as

supplementary power sources in manufacturing and medical equipment, where even momentary

drops in voltage can be critical. They serve to compensate for uneven voltage levels with solar

panels and even as primary power sources in small devices. Most significantly, Lithium Ion

Capacitors are becoming a preferred backup solution for power interruption in servers and other

devices.

Principles and Features of Lithium Ion Capacitors as Compared to

EDLCs

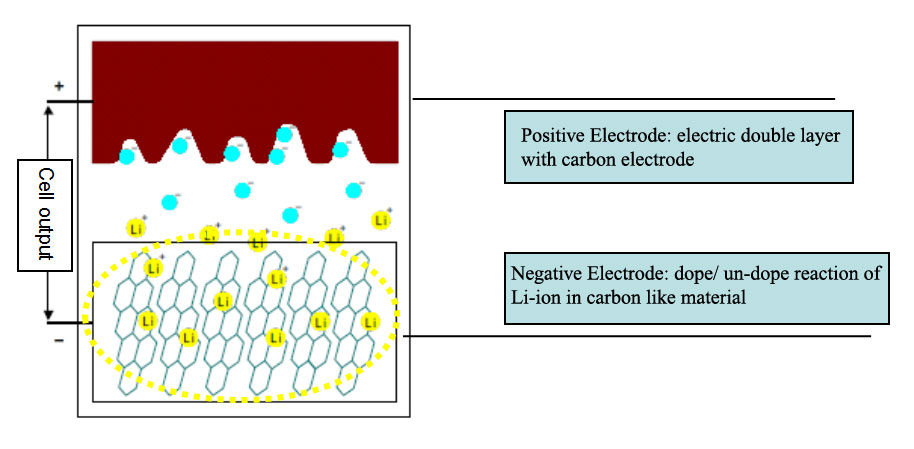

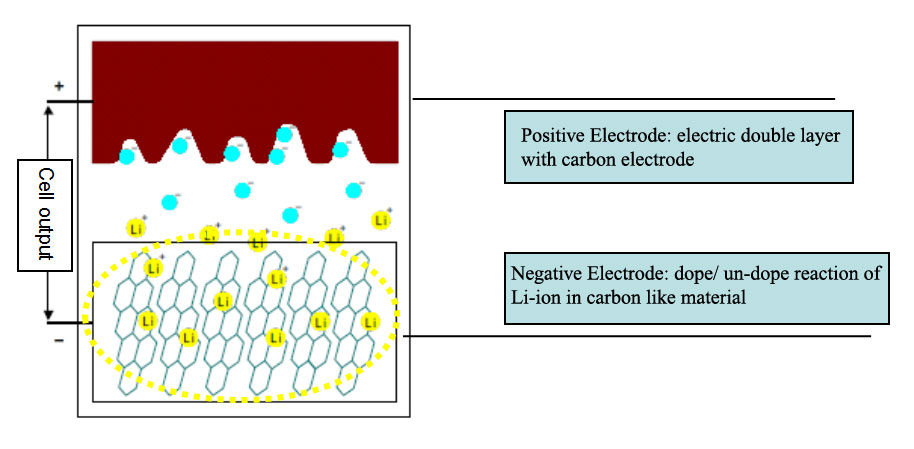

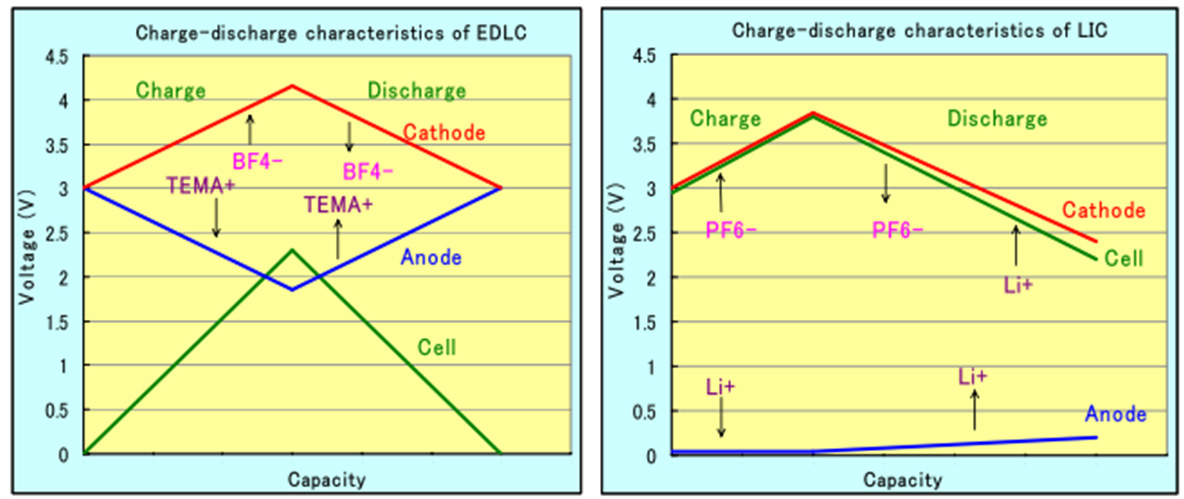

Lithium Ion Capacitors are hybrid capacitors that use a carbon-based material as the negative

electrode that can be doped with lithium. Just as in a conventional EDLC, they use activated

carbon for the positive electrode.

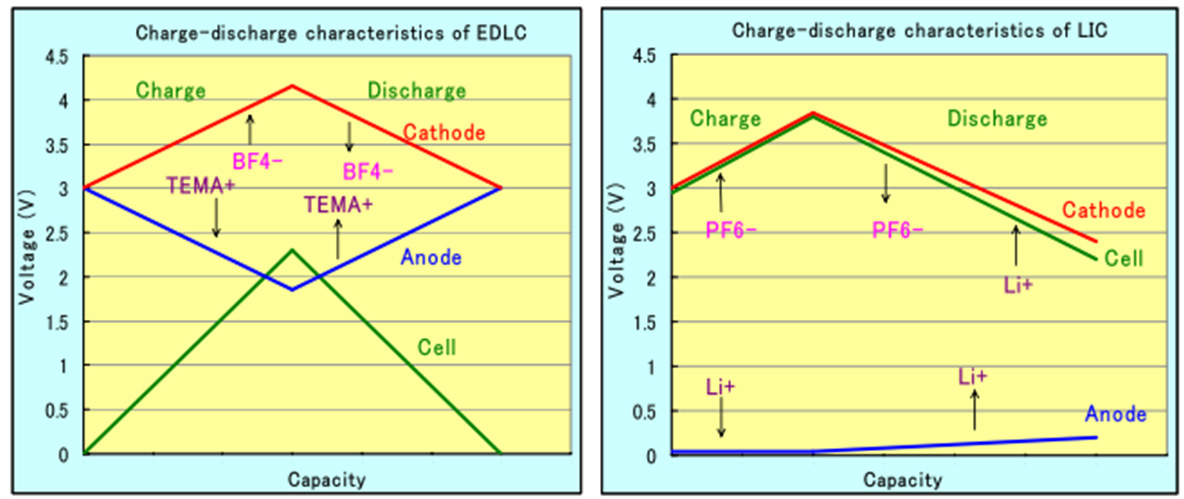

Metallic lithium, electrically connected to the negative electrode, forms a local battery at the same time as immersion of the electrolytic solution. Then, doping of Lithium Ions begins on the carbon-based material at the negative electrode. Once doping is complete, the initial voltage of the Lithium Ion Capacitor drops to 3V or less as the electric potential of the negative electrode almost matches that of lithium. Therefore, compared to the charging/discharging potential of conventional EDLCs, a higher voltage can be obtained by using Lithium Ion Capacitors without a high potential at the positive electrode, which results in improved reliability in Lithium Ion Capacitors.

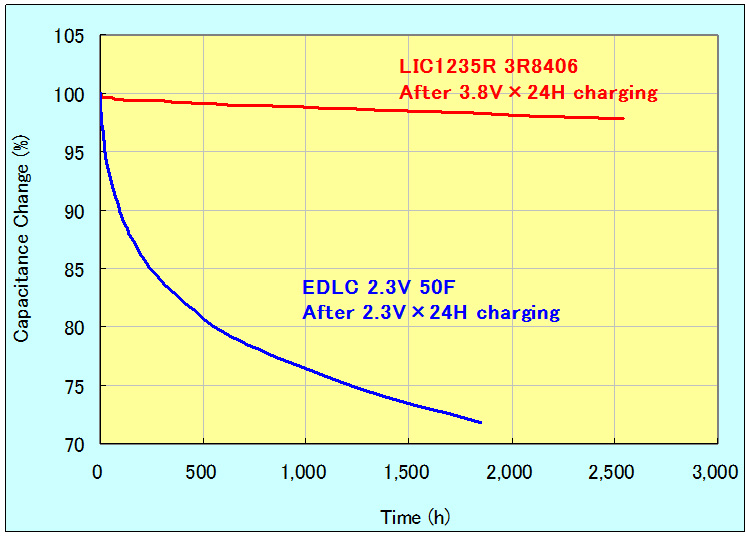

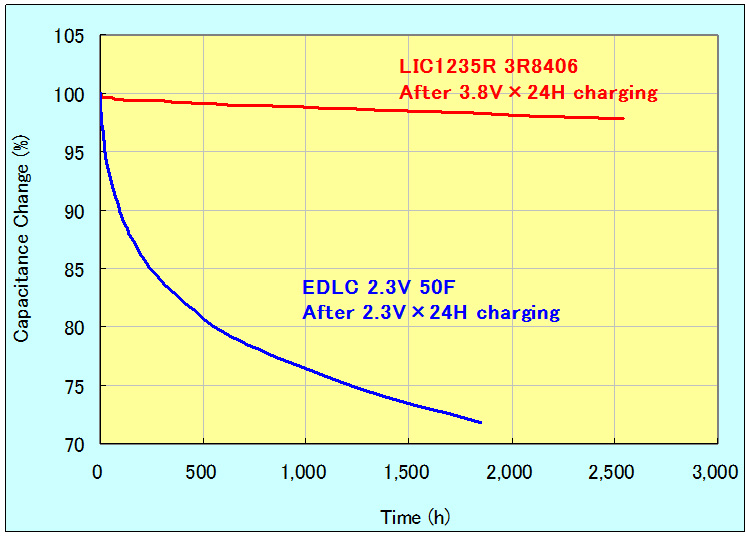

1. Self-Discharge Characteristics

One major feature of the Lithium Ion Capacitor is its excellent 'self-discharge property,' which is

enabled by pre-doping of lithium to the negative electrode to stabilize the potential of the

negative electrode, The graph below shows the self-discharge property of the cylinder type

Lithium Ion Capacitor with 40F charged for 24 hours in 3.8 V at a temperature of 25ºC and those

of a symmetrical type EDLC whose capacitance is similar to the Lithium Ion Capacitor. As seen

here, the symmetrical type EDLC has a large self-discharge. After a month under 25ºC, its

voltage lowered to 80% of the initial volt-age. In contrast, the Lithium Ion Capacitor shows far

better self-discharge. It can maintain a voltage of over 3.7 V even 100 days later under a

temperature of 25ºC.

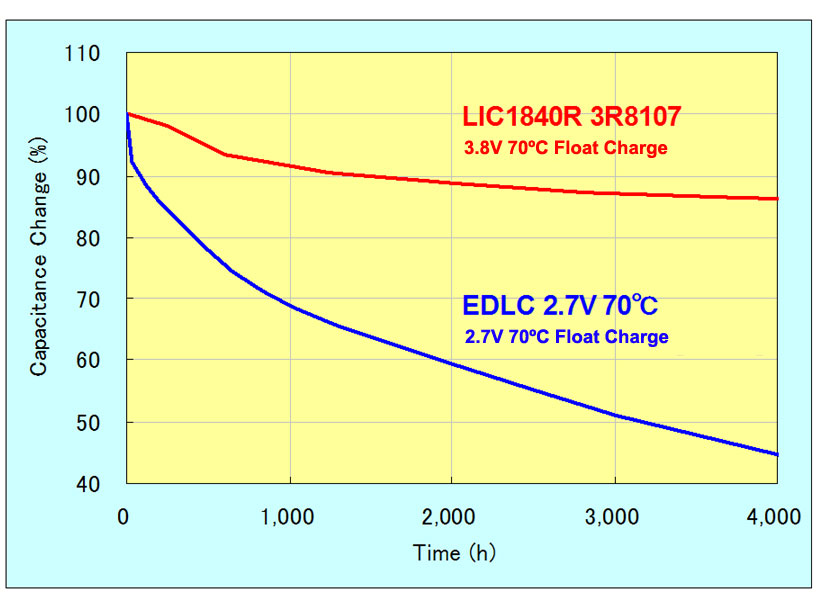

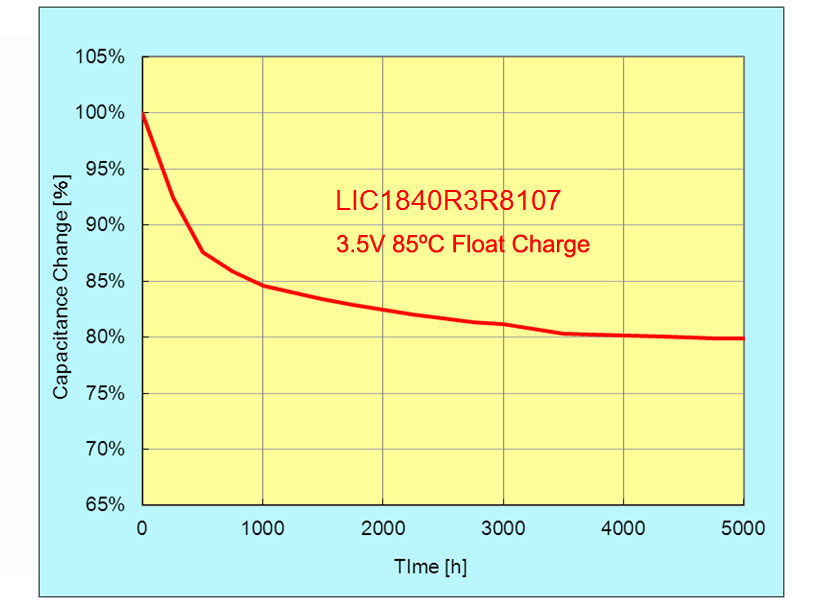

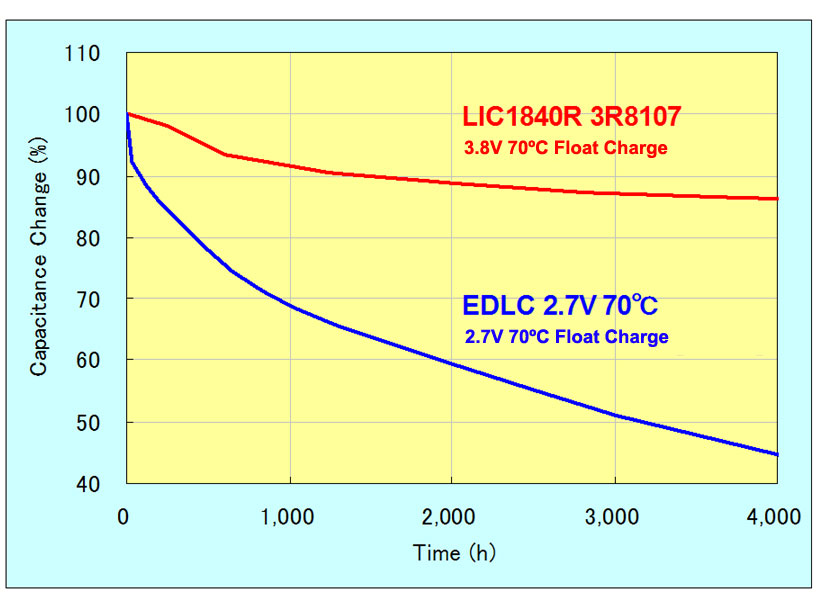

2. Float Charge Characteristics

The float charge characteristics (consecutive-charge) of a cylinder type Lithium Ion Capacitor

and symmetrical EDLC whose capacitance is almost similar to the Lithium Ion Capacitor under a

temperature of 70ºC. As mentioned in "Principles and Features of Lithium Ion Capacitors", one

of the features of Lithium Ion Capacitors is that even with a high voltage charge of 3.8 V, the

capacitors can lower their potential at the positive electrode to less than that of conventional

symmetrical EDLC, which prevents their float charge from deteriorating and makes them highly

reliable.

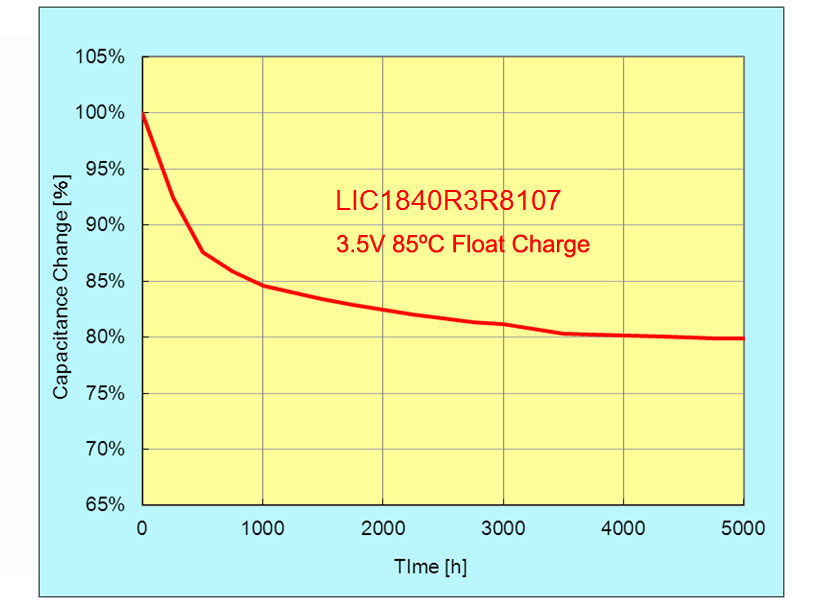

Moreover, charged at 3.5 V, the float charge characteristics (consecutive-charge) of a cylinder type Lithium Ion Capacitor under a high temperature of 85ºC shows good results with about 80% of the initial voltage maintained even 5,000 hours later.

3. Charge/Discharge Cycle Characteristics

Unlike Lithium Ion secondary batteries, Lithium Ion Capacitors are chemically stabilized

products that employ the adsorption-desorption reaction of ions so that they do not cause a

crystalline change at the positive electrode during the charge-discharge cycle. In addition, lithium

is doped to a carbon-based material of the negative electrode in advance and the Lithium Ion

Capacitor can be designed to lower the Lithium Ions availability in the negative electrode. This

gives the Lithium Ion Capacitor to excellent charge/discharge cycle characteristics of over 100

thousand times, equivalent to that of conventional symmetrical type EDLCs. Some of these

applications are already in practical use.

4. Temperature Characteristics

A stable discharge is obtained even at high temperatures and a volume-maintenance rate of over

60% is achieved even at a low temperature of -20ºC. In addition, a strong volume-maintenance

rate of about 50% is achieved at extremely low temperatures, even when affected by the voltage

drop caused by lesser mobility of ions in the electrolytic solution. With that, it is clear that the

Lithium Ion Capacitor has good temperature characteristics.

5. High Energy Density

The maximum voltage of Lithium Ion Capacitors, 3.8 V, is higher than that of a symmetric

type EDLC, and the capacitance is twice that of the EDLC. Therefore, the energy density of

Lithium Ion Capacitor is quadruple that of the EDLC, based on the formula of

"Q=1/CV2".

As the capacitance of this Lithium Ion Capacitor is about 88 mAh at the range of 3.8 V to 2.2 V,

the Lithium Ion Capacitor has strong characteristics in discharge at the rate of 1C to 100C. As it

can obtain about 60% of the discharged capacity at a discharge rate of 100C, the Lithium Ion

Capacitor can be said to be a capacitor with excellent discharge characteristics in high output. In a

Ragone plot comparison of a cylinder type Lithium Ion Capacitor with 200F and a conventional

symmetric EDLC whose size is similar to the Lithium Ion Capacitor, the energy density of the

Lithium Ion Capacitor is 8.6WH/kg, far larger, about 6.5 times larger, than the 1.5Wh/kg of the

conventional EDLC.

6. Space Savings

Thanks to its high energy density, multiple EDLCs can be replaced with one Lithium Ion

Capacitor. In applications such as servers and integrated circuits that use dozens of EDLCs, this

can result in significant space savings allowing for an overall reduction in space or more space

between each component. Utilizing fewer capacitors also helps improve thermal design by

reducing the number of heat generating components.

Safety of Lithium Ion Capacitor

Using a carbon-based material doped by Lithium Ions at the negative electrode may create

concerns about the safety, similar to Lithium Ion Batteries (LIB). However, the material

composition of their positive electrodes are very different: LIB uses metal oxide and Lithium Ion

Capacitor uses carbon-based materials such as activated carbon, which does not contain oxygen.

This differentiates their reactions when an internal short-circuit occurs.

In LIBs, when an internal short-circuit occurs, the temperature of the internal cell rises by the

short-circuit current. A following reaction between the negative electrode and the electrolytic

solution causes an increase in the pressure of the internal cell, followed by a collapse of the

crystal at the positive electrode and a release of oxygen in oxidation products of the positive

electrode. This causes another thermal runaway, and, in some cases, an ignition or an explosion

might occur due to a further rise in pressure of the internal cell and vaporization of the

electrolytic solution.

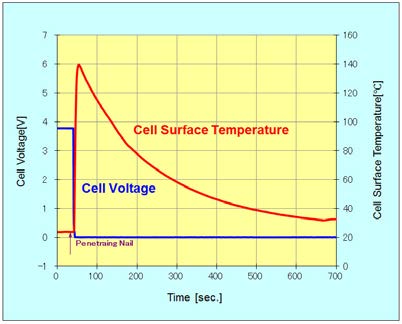

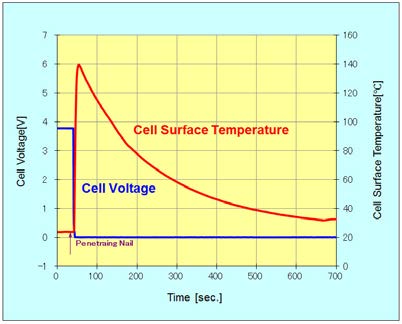

In contrast, the internal pressure of the cell also rises in Lithium Ion Capacitors, but after that, thanks to the difference of the materials in the positive electrodes, the thermal runaway phenomenon will not occur and the reaction quietly finishes with the opening of the safety valves. Thus, Lithium Ion Capacitors will not cause any serious accidents such as fires or explosions by the thermal runaway even of an internal short-circuit or other accident occurs, thanks to the difference of the material of its positive electrode compared to LIBs. Lithium Ion Capacitor can be said to be as logically safe an energy device as conventional non-aqueous solvent based EDLCs. Below are the results of a nail penetration test to a cylinder type Lithium Ion Capacitor with 200F, assuming an actual internal short-circuit.

These results show that the Lithium Ion Capacitor is a safe device. Even if the temperature of an

external wall of the cell increases to 100ºC after short-circuiting, the temperature gradually

decreases and the cell does not cause serious problem such as major deformations or explosions.

With these results, Lithium Ion Capacitor is a good device equivalent to the symmetrical type

EDLC in safety, has a number of features such as that it does not cause the thermal runaway even

with rising internal cell temperatures, unlike LIBs, it does not contain any metal oxides as a

material of the positive electrode. In addition, if an internal short-circuit should occur, internal

short-circuits from an elution in base materials of the negative electrode are unlikely as the

potential of the negative electrode does not exceed the elution potential of Cu.

Lithium Ion Capacitor Applications

• Backup power source in servers and storage devices for integrated circuits, processors,

memory and more. The Lithium Ion Capacitor is ideal for tight, high temperatures spaces, as it provides energy density up to 4 times that of EDLCs, superior heat performance characteristics, voltage maintenance over time and low deterioration of floating charge.

• Power sources for small appliances, applying the quick rechargeable, lightweight, and

low self-discharge features.

• Energy devices combined with photovoltaic cells or wind power generators (such as

raised markers, light-emitting load signs, street lights, small LED illuminations)

• Auxiliary power devices for energy saving devices (such as rapid drum heating in copiers

and on star-up for projectors)

• Computerized devices for automobiles, such as idling-stop devices, drive recorders and

Author Biography

Atsuya Sato is the field application engineering supervisor in TAIYO YUDEN's ECD (Electric

Chemical Device) Project of the New Business Planning Development Division. He has worked

in TAIYO YUDEN ENERGY DEVICE CO., LTD. (formerly Shoei Electronics Co., Ltd.) Osaka,

Japan office, where he oversaw business with European, Chinese and South Korean mobile phone

manufacturers. After company restructuring in 2010, Mr. Sato moved to TAIYO YUDEN Co.,

Ltd. ECD Project, and currently supports sales offices in Europe, the United Sates and Singapore.

About TAIYO YUDEN

Since its establishment in 1950, TAIYO YUDEN has invested in research and development to

offer leading-edge technology to capacitors, inductors, circuit products, Surface Acoustic Wave

(SAW)/Film Bulk Acoustic Resonator (FBAR) devices, energy devices and recording media

under the philosophy that the process of product commercialization starts with material

development. TAIYO YUDEN's extensive range of products demonstrates world-leading support

to development and progress in the information technology and electronics industries. The

company's North American affiliate, TAIYO YUDEN (U.S.A.) INC., operates sales and

engineering offices in Chicago IL, Boston MA, Dallas TX, Denver CO, San Diego CA, San Jose

CA, and Ontario, Canada.

For more information, please visit:

Source: http://www.mouser.com/pdfdocs/LithiumIonCapacitorWhitePaper_Final_Rev_20140619.PDF

CONSUMER MEDICINE INFORMATION Ask your doctor or pharmacist if you have any • Any of the ingredients listed at the end of this leaflet. questions about why Chemmart® Thrush one dose + Some of the symptoms of an allergic reaction may cream has been recommended for you. Your doctor or pharmacist may have recommended Chemmart® Thrush one dose + cream for another reason.

Am J Transl Res 2012;4(2):219-228 www.ajtr.org /ISSN:1943-8141/AJTR1202002 Original Article Identification of an interleukin 13-induced epigenetic signature in allergic airway inflammation Aik T Ooi1, Sonal Ram1, Alan Kuo1, Jennifer L Gilbert1, Weihong Yan2, Matteo Pellegrini3, Derek W Nickerson1, Talal A Chatila4, Brigitte N Gomperts1,5,6,7 1David Geffen School of Medicine at UCLA, Department of Pediatrics, Mattel Children's Hospital, Los Angeles, CA 90095, USA; 2Department of Chemistry and Biochemistry, University of California, Los Angeles, CA, 90095 USA; 3Department of Molecular, Cell and Developmental Biology, University of California, Los Angeles, CA, 90095 USA; 4Division of Immunology, The Children's Hospital and Department of Pediatrics, Harvard Medical School, Boston MA 02115; 5David Geffen School of Medicine at UCLA, Department of Medicine, Division of Pulmonary and Critical Care Medicine, Los Angeles, CA 90095, USA; 6Broad Stem Cell Research Center at UCLA, Los Angeles, CA, 90095, USA; 7Jonsson Comprehensive Cancer Center at UCLA, Los Angeles, CA, 90095, USA Received February 12, 2012; accepted March 22, 2012; Epub April 10, 2012; Published April 30, 2012 Abstract: Epigenetic changes have been implicated in the pathogenesis of asthma. We sought to determine if IL13, a key cytokine in airway inflammation and remodeling, induced epigenetic DNA methylation and miRNAs expression changes in the airways in conjunction with its transcriptional gene regulation. Inducible expression of an IL13 trans-gene in the airways resulted in significant changes in DNA methylation in 177 genes, most of which were associated with the IL13 transcriptional signature in the airways. A large number of genes whose expression was induced by IL13 were found to have decreased methylation, including those involved in tissue remodeling (Olr1), leukocyte influx (Cxcl3, Cxcl5, CSFr2b), and the Th2 response (C3ar1, Chi3l4). Reciprocally, some genes whose expression was sup-pressed were found to have increased methylation (e.g. Itga8). In addition, miRNAs were identified with targets for lung development and Wnt signaling, amongst others. These results indicate that IL13 confers an epigenetic methyla-tion and miRNA signature that accompanies its transcriptional program in the airways, which may play a critical role in airway inflammation and remodeling. Keywords: Epigenetics, miRNA, DNA methylation, allergic airway disease