Levitra enthält Vardenafil, das eine kürzere Wirkdauer als Tadalafil hat, dafür aber schnell einsetzt. Männer, die diskret bestellen möchten, suchen häufig nach levitra kaufen ohne rezept. Dabei spielt die rechtliche Lage in der Schweiz eine wichtige Rolle.

Microsoft word - bsria report 50454-1.doc

Testing and CFD Study of Airius

Destratification Fans

Report 50454/1

February 2007

Carried out for: Airius Europe Ltd

Compiled by: John

Quality Approved:

GREG KING BSc MSc M.InstR

This report must not be

BSRIA Limited

reproduced except in full without the written approval of an

Old Bracknell Lane West, Bracknell, Berkshire RG12 7AH UK

executive director of BSRIA. It is

T: +44 (0)1344 465600 F: +44 (0)1344 465626

only intended to be used within

the context described in the text.

E: [email protected] W: www.bsria.co.uk

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS

CONTENTS

1 INTRODUCTION. 2

2 AIR FLOW MEASUREMENT . 3

3 AIR JET MEASUREMENTS . 5

3.1 Test method . 5

4 CFD MODEL SETUP. 6

4.1 Laboratory (Shed type building). 6 4.2 Retail outlet . 7

5 CFD RESULTS . 8

5.1 Laboratory (shed type building) . 8 5.2 Retail Outlet. 12

6 DISCUSSION OF RESULTS . 13

BSRIA PRODUCTS AND SERVICES . 14

Airflow test arrangement . 3

Airius 10, flow vs pressure chart . 4

Airius 25, flow vs pressure chart . 4

Measured airspeeds (left) and calculated air speeds (right) . 5

Modelled geometry . 6

Modelled geometry . 7

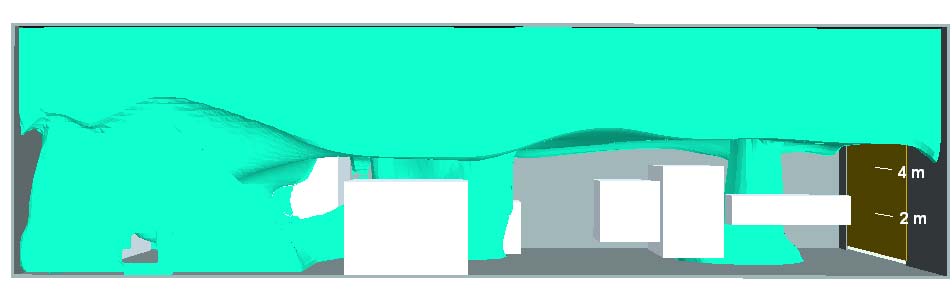

Temperature contours along centreline. 8

Temperature contours with three fans installed . 8

Temperature contours with four fans installed . 9

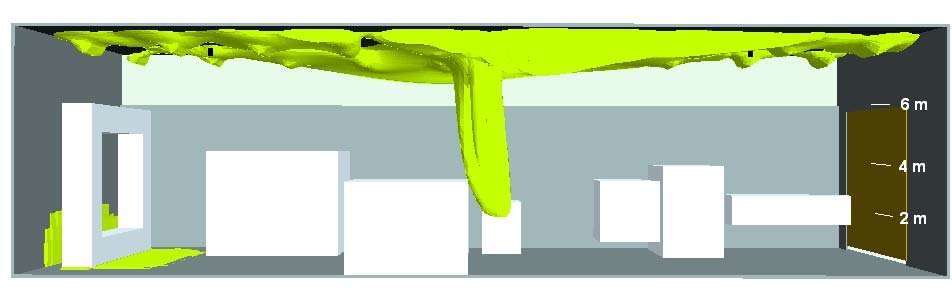

Zone with temperatures above 20°C (no fans) . 10

Zone with temperatures above 20°C (with three fans) . 10

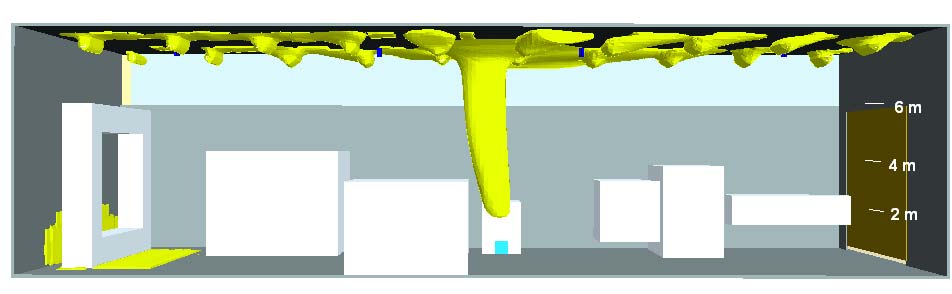

Zone with temperatures above 20°C (with four fans). 10

Zone with temperatures above 21°C (no fans) . 11

Zone with temperatures above 21°C (with three fans) . 11

Zone with temperatures above 21°C (with four fans). 11

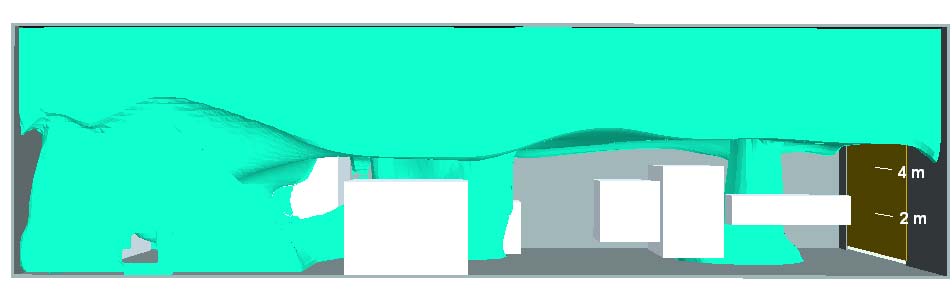

Temperature contours (no fans) . 12

Temperature contours (with fans) . 12

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS INTRODUCTION

1 INTRODUCTION

Airius Europe distributes a range of novel destratification fans. These fans are thought to be unique in that the fan is enclosed in a casing, which incorporates guide vanes and a nozzle so that the air is thrown in a narrower jet. This report presents the results of tests carried out on the model 10 and model 25 fan as well as computer simulations of the fans in operation. The test work firstly involved measuring the flowrate through the fans, so that these could be accurately set in the CFD models. The flowrates were measured in accordance with ISO 5801, in a Type A configuration (free inlet and outlet). The jet of air from the fans were then measured to ensure the throw from the fans was correctly represented in the CFD simulations. These measurements are beneficial since the geometry of the nozzle and the presence or absence of swirl can influence the jet spread.

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS

VOLUME FLOW MEASUREMENT

VOLUME FLOW MEASUREMENT

The fans were tested in accordance with ISO 5801, in a Type A configuration (free inlet and outlet). The test arrangement is in Figure 1 shown below.

Airflow test arrangement

The Airius unit was mounted on the plenum, with its inlet within the chamber. The variable speed fan was used to adjust the pressure in the plenum. This allowed the flow to be measured with a range of pressures across the test item.

2.2 INSTRUMENTATION

Equipment used during testing

Name of Item

Calibration Due on.

50 mm Nozzle Box

12 July 2008

Selection box – pressure tapping selection

24 November 2006

FCO510 Micro-manometer

27 March 2007

Temperature probe

28 March 2007

Absolute pressure sensor

28 March 2007

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS

VOLUME FLOW MEASUREMENT

VOLUME FLOW RESULTS

Plots of flow rate against static pressure are shown in Figure 2 and Figure 3 below. In summary, under free air conditions the Airius 25 had a flow rate of 161 l.s-1 and the Airius 10 had a flow rate of 101 l.s-1, when corrected to standard temperature and pressure.

Airius 10, flow vs pressure chart

Flow rate against static pressure for an Airius 10 destratification fan, tested to ISO 5801 type A.

Flow rate corrected to 1013.25mbar and 20oC (l/s)

Airius 25, flow vs pressure chart

Flow rate against static pressure for an Airius 25 destratification fan, tested to ISO 5801 type A.

Flow rate corrected to 1013.25mbar and 20oC (l/s)

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS

AIR JET MEASUREMENTS

AIR JET MEASUREMENTS

The jet of air created by the model 10 and model 25 destratification fans were measured using hot wire anemometry. Close to the fan discharge where airspeeds were highest, a vane anemometer was used since these speeds exceeded the range of suitability of the hot wire anemometers. The tests were conducted under approximately isothermal conditions and the fans were tested in a horizontal position. Eleven anemometers were attached along a vertical pole. A grid of points (9x10) was marked out on the floor, covering an area of 1.2 x 4.2 m. The pole of anemometers was then moved from grid point to grid point and all eleven readings were taken at each pole location. This gave a total of 990 air speed measurements (9x10x11). Both fans were tested in this manner. In order to check the CFD code can correctly predict the spread of the jet, comparisons were made between the measured air speeds and isothermal CFD calculations. Figure 4 shows a comparison of air speeds using colour coded planes through the axis of the jet. The left side show the experimental measurements (grid points are marked on the floor), the right side shows the CFD calculations. A very close correspondence is seen.

Measured airspeeds (left) and calculated air speeds (right) for model 10

fan

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS

CFD MODEL SETUP

The flovent CFD code was used to simulate airflows and temperatures three-dimensionally in the example buildings. Steady state results are presented (ie temperatures and airflow patterns after sufficient time for all values to stabilise to constant values).

LABORATORY (SHED TYPE BUILDING)

The geometry of the building used to test the model 25 fan is shown in Figure 5. The building is loosely based on one of the BSRIA test laboratories. Floor plan dimensions are 10m x 30m and fan height is 7.5 m. Various test rigs are distributed around the space. One side of the building is glazed at high level. Fabric losses are based on an outdoor temperature of 2°C and U values of the structure set to coincide with Part L of the 2002 building regulations. To further help the space to stratify a 1.5 cm gap is modelled under the loading door and a similar open area is assumed at high level. By including these openings in the model, cold air tends to flow under the door and contribute to the stratification. Lighting is assumed to amount to 20 W/m2. This is implemented as 20 heated blocks at ceiling level, each one releasing 300 W. An oil-fired heater provides further heating. This is assumed to supply 60 l.s-1 of air at 80°C. In actuality the heater provides a much greater flow at a lower temperature, but this creates a strong jet that helps to mix the air and reduce stratification. The objective of this work was to investigate the ability of the Airius fans to destratify the space, so the modelled building was deliberately set to encourage stratification. When simulating the influence of the fans, three, model 25 fans, were arranged along the centre line of the building. Hence a floor area of 100 m2 per fan, is tested. A further simulation was then carried out with four fans (hence 75 m2 per fan)

Modelled geometry

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS

4.2 RETAIL

The building selected to test the model 10 fan, was one corner of a retail outlet. The geometry is shown in Figure 6. An area 10 x 10 m is modelled, with a ceiling height of 3 m. In order to limit the model to a floor plate of 10 m x 10 m, airflows between the modelled region and the rest of the store are prevented (ie the corner is partitioned off from the rest of the store for modelling purposes). Lighting is modelled using nine heated blocks distributed along the ceiling, each one releasing 133 W. This gives a lighting load of 12 W/m2. To encourage stratification an outdoor temperature of 2°C is modelled and full height glazing is set along both external walls. U values of the building are set to correspond with the requirements of Part L of the 2002 building regulations. To heat the space, air at 24°C is supplied through four ceiling mounted diffusers. Two extract diffusers remove air from the space. The supply diffusers are of a four way throw type and supply 160 l.s-1each (extracts therefore remove 320 l.s-1). This results in an air change rate of 7.7 ACH.

Modelled geometry

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS CFD

LABORATORY (SHED TYPE BUILDING)

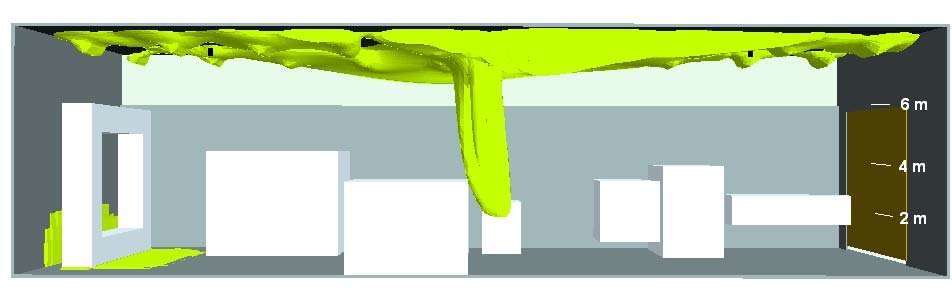

In Figure 7 temperature contours are plotted. A colour coded vertical plane through the building shows how temperatures vary with location. The colours relate to temperatures as indicated in the legend. Cold air leaks under the door and spreads along the floor, creating a large region under 17°C. A stratified temperature distribution is predicted with warm air floating towards the roof. Figure 8 shows the corresponding result with the three fans operating. Since the contour plane passes through the fans, the warm jets can be seen projecting downwards. At the opposite side of the building from the door, destratification is almost complete. Close to the door, the steady flow of air into the building maintains a cold spot at ground level, but the improvement is obvious.

Temperature contours along centreline

Temperature contours with three fans installed

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS CFD

Figure 9 below shows the same building with four fans operating. A further improvement over figure 8 is seen; with an even more uniform temperature distribution.

Temperature contours with four fans installed

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS CFD

In Figure 10 the region with temperatures above 20°C is marked in green. This warm air is seen to float towards the top of the space and most of the occupied area is less than 20°C. The corresponding picture with three fans operating is shown in Figure 11. The layer of warm air, floating above occupants is reduced. Some of the columns of warm air from the fans are seen pouring down onto the floor. In figure 12 the scenario with four fans operating is shown. The blanket of warm air floating above the heads of the occupants is further reduced and the columns of warm air from the fans are clearly seen. The plume of warm air from the heater is also clearly visible.

Figure 10

Zone with temperatures above 20°C (no fans)

Figure 11

Zone with temperatures above 20°C (with three fans)

Figure 12

Zone with temperatures above 20°C (with four fans)

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS CFD

Figure 13, Figure 14 and Figure 15 shows the regions with air temperatures above 21°C without fans, with three fans and with four fans respectively. These again show how the quantity of warm air near the ceiling is reduced due to the fans. With the four fans running air temperatures above 21°C only arise near lights or in the warm air plume from the heater.

Figure 13

Zone with temperatures above 21°C (no fans)

Figure 14

Zone with temperatures above 21°C (with three fans)

Figure 15

Zone with temperatures above 21°C (with four fans)

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS CFD

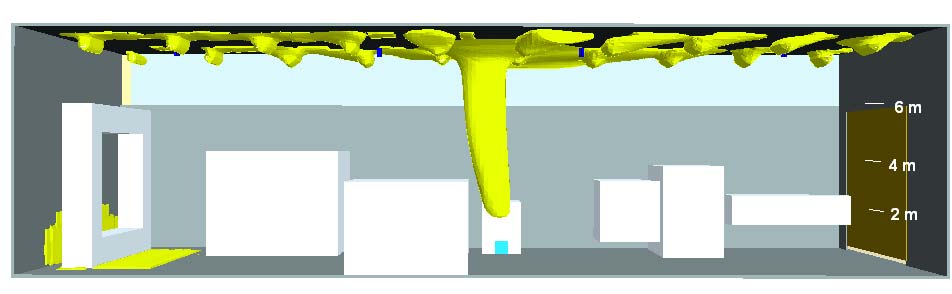

5.2 RETAIL

In Figure 16 temperature contours are plotted on planes through the modelled region of the retail outlet. Due to the cooling effect of the glazing and heating from ceiling diffusers, a stratified temperature distribution is predicted. In Figure 17 the corresponding result is plotted for a scenario with a model 10 fan installed. The action of the fan can be seen in the centre plane as a warm jet descending from the ceiling. The overall effect is to reduce the stratification. The constant downdraft of cool air from the glazing means that some stratification persists especially to the left of the figures.

Figure 16

Temperature contours (no fans)

Figure 17

Temperature contours (with fans)

The major inputs, which gave rise to this result are:

• Full height glazing on two sides of the space • An outdoor temperature of 2°C • Heating through ceiling-mounted, four way throw type, diffusers

BSRIA Report 50454/1

TESTING AND CFD STUDY OF AIRIUS DESTRATIFICATION FANS

DISCUSSION OF RESULTS

6 DISCUSSION

Tests in accordance with ISO 5801 were conducted to determine the flowrates for the two Airius destratification fans. A flowrate of 101 l.s-1 was measured for the model 10 destratification fan and a flowrate of 161 l.s-1 was measured for the model 25 fan. Air speed measurements were made across a grid of points in front of both fans to examine the spread of the jet and to ensure the CFD software could accurately represent this, in simulations of room airflow. A narrow jet was observed from these measurements, possibly because the fan incorporated vanes apparently designed to remove swirl. A good correlation was observed between CFD simulations and measurements of air speed. A CFD model of a shed type building was used to examine the performance of the model 25 fan. Stratification in the test building was ensured by a combination of low outdoor temperatures, leakage under the loading door and heating via a low velocity air supply. The initial model without fans showed a stratification of 17.0 - 22.6 °C between floor and roof at the centre point of the building. With four fans operating, this stratification reduced to 19.8 – 21.6 °C at the centre point of the building. The extent to which stratification is reduced is dependant on the location. The best improvements are seen near the back wall of the laboratory, well away from the influence of the leaking door. The result is also dependant on the height at which the temperatures are read. This comparison is based on an ankle level measurement and ceiling level measurement. A CFD model of one corner of a retail outlet was used to examine the performance of the model 10 fan. Stratification in the test building was ensured by a combination of low outdoor temperatures, full height glazing on the external walls and heating from ceiling mounted diffusers. With no fan fitted a stratification of 18.3 – 22.2 °C was observed in the centre of the space. With the fan operating a stratification of 19.1 – 21.7 °C was observed. As for the previous example, the influence of the fan varied throughout the space. Improvements were greatest furthest away from the influence of the cold glazing. As in the previous example the result is dependant on the height of the temperature measurements as well as the position in the room. Less stratification would be apparent if these temperatures were quoted at waist height instead of ankle height.

BSRIA Report 50454/1

BSRIA products and services

BSRIA is a consultancy, test and research organisation helping construction and building services companies to become more efficient and effective. Our 128-strong team of building services experts can provide the best solutions to the most searching problems ensuring complete confidentiality and individual service at all times.

Working with BSRIA gives you confidence in design, added value in manufacture, competitive advantage in marketing and strategy, profitable construction, effective commissioning and accurate measurement, and efficient building operation and maintenance.

BSRIA membership enables organisations to demonstrate that they are leading the industry through innovation and best practice.

Across all

Construct

Manufacture

Management &

activities

Marketing

Instrument solutions

Design quality and

Site productivity

Strategic Services

Testing and certification

Business strategy

process guidance

improvement

Maintenance strategy

to recognised standards

Strategic planning

Business focussed

Bespoke assignments, or

Design validation

maintenance schedules

one day consultancies

On site services

Physical modelling

Building management

Air handling units

Procurement advice

Thermal modelling

Modular training,

feedback and toolbox

Procurement advice

Atomising oil nozzles

Business Performance

Information

BREEAM assessments

O&M benchmarking

IBSEDEX – building

Proof of performance

Health and safety audit

Blockwork porosity

services abstracts

Energy efficiency

Chilled ceilings

Standard & bespoke

Management

assessments

Partnering workshops

Push information (2006)

(see list under manufacture)

Coolers and condensers

Marketing strategy -

Displacement ventilation

Whole life costing

Control system surveys

confidential studies on:

Life cycle analysis

Water and air quality

Expansion vessels

Training

Consultancy in:

Approval inspections

Internal environment

Specialist topics:

monitoring

Thermal imaging of

Flue lining systems

Whole life costing

Cooling of IT rooms

Comfort measurement

Technical appraisal

Introduction to building Sustainability

Raised floor leakage

Sick building syndrome

Distributions and pricing

Metal flues, chimneys,

Indoor air quality

fittings and terminals

Water conservation

Building envelope

Market research - size

Pollution monitoring

leakage test (for Part L)

and structure of markets

Facilitation and

Refrigeration equipment

Control strategies

Roof inspections

Plant and system

Heating, air conditioning,

workshops

Fire stop testing

Specialist enclosure

plumbing and

Offsite fabrication

sanitaryware, controls,

Partnering workshops

Proof of performance

Performance checks

Testing thermal

renewables, structured

and installability

Maintenance tasks

performance, emissions,

(see also design)

cabling, FM and

EMC, MTBF, noise

Secretariat support

Site surveys and

contracting

condition monitoring

Testing to client

Confidential studies

Plant condition surveys

Published reports

Constructing Excellence

Vibration and sound

Global studies annually

Energy labelling

Non-destructive testing

In depth studies

Technical authoring

Product failure analysis

Statistics clubs

Committee facilitation

Attitudinal studies

and support

(failures - electrical plant,

Standards development

damp, underfloor heating,

Customer research

Research management

chilled ceilings)

Ultrasonic pipe work

Customer satisfaction

Expert witness work

Product acceptability

Design of test facilities

Understanding clients'

Electrical surveys

Support for new product

Magnetic field survey

Market research

development

Lighting level and

techniques used:

For due diligence and legal

Personal interview

compliance

Telephone, fax and web

Questionnaire design

Source: http://www.airius.si/dokumenti/brosure/bsriaReport.pdf

2001 · 2:142–149 © Springer-Verlag 2001 J. Rovira1 · R.Tremosa1 · A. Gilabert2 · M.Torralba21 Grup de Recerca en Economia de la Politica Social,Universitat de Barcelona,Spain2 Servei Català de la Salut,Unitat de Planificació Farmacèutica,Generalitat de Catalunya,Spain The role of prices in drug expenditure analysis

A Comparative Study on Facially Expressed Emotions in Response to Basic Tastes Wender L. P. Bredie, Hui Shan Grace Tan & Karin Wendin Chemosensory Perception ISSN 1936-5802Chem. Percept.DOI 10.1007/s12078-014-9163-6 Your article is protected by copyright and all rights are held exclusively by European