Levitra enthält Vardenafil, das eine kürzere Wirkdauer als Tadalafil hat, dafür aber schnell einsetzt. Männer, die diskret bestellen möchten, suchen häufig nach levitra kaufen ohne rezept. Dabei spielt die rechtliche Lage in der Schweiz eine wichtige Rolle.

Igs100 instruction manual

Implantable Glucose Sensor

World Precision Instruments

World Precision Instruments

About thIS MANuAl .1

Notes and Warnings .2

INStruMeNt deScrIPtIoN .2

Parts list .2unpacking .2

oPerAtINg INStructIoNS .3

conditioning the Sensor .3Preparing Solution for calibration .3calibrating the IgS100 .3

SeNSor cAre ANd MAINteNANce .5

Storing the Sensor .5Maintaining the Sensor .5Sterilizing the Sensor .5

troubleShootINg .6

SPecIfIcAtIoNS .6

claims and returns .7repairs .7

Copyright 2009 by World Precision Instruments, Inc. All rights reserved. No part of this publication may be reproduced or translated into any language, in any form, without prior written permission of World Precision Instruments, Inc.

World Precision Instruments

World Precision Instruments

AbOUT ThIS MANUAL

the following symbols are used in this guide:

this symbol indicates a cAutIoN. cautions warn against actions that can cause damage to equipment. Please read these carefully.

this symbol indicates a WArNINg. Warnings alert you to actions that can cause personal injury or pose a physical threat. Please read these carefully.

NoteS and tIPS contain helpful information.

Fig. 1–IGS100 sensor

Fig. 2–Tip of the sensor showing the coil holding the enzyme saturated cotton plug. The diameter of the coiled tip is about 600µm.

World Precision Instruments

IGS100 implantable glucose sensor for real-time monitoring is an

amperometric microsensor that can be used in vivo. the implantable,

sensing tip is slightly larger than a half-millimeter in diameter. the tip is

comprised of a metal coil with an enzyme-soaked cotton core. A proprietary

coating covers the entire tip. As the sensor is used, the enzyme is consumed.

the tip design resists contamination from biological materials, which

significantly improves the life of the sensor. depending on measurement

conditions, IGS100 may be used in vivo for weeks or even months. When

not in use, it has a six-month shelf life.

Notes and Warnings

NOTE: the sensor must be polarized for at least 4 hours in 5mM glucose

solution prior to use.

INSTRUMeNT deSCRIpTION

parts List

After unpacking, verify that there is no visible damage to the sensor. Verify

that all items are included:

(1) IGS100 glucose sensor (1) Instruction Manual(1) Sensor Performance evaluation

Unpacking

upon receipt of this sensor, make a thorough inspection of the contents and

check for possible damage. Missing cartons or obvious damage to cartons

should be noted on the delivery receipt before signing. concealed damage

should be reported at once to the carrier and an inspection requested.

Please read the section entitled "claims and returns" on page 7 of this

manual. Please contact WPI customer Service if any parts are missing at

941.371.1003 or [email protected].

the IGS100 sensor is shipped in a sealed, rigid plastic, hinged box with

foam padding to avoid damage to your sensor during shipment. KeeP the SeNSor StorAge boX and all the documentation in a safe

place. the storage box allows you to store the sensor safely with the tip

suspended. the test date and serial number of each sensor is printed on the bottom of its box. use of the sensor should begin within 30 days of receipt.

World Precision Instruments

Returns: do not return any goods to WPI without obtaining prior approval

(rMA # required) and instructions from WPI's returns department. goods

returned (unauthorized) by collect freight may be refused. If a return

shipment is necessary, use the original container, if possible. If the original

container is not available, use a suitable substitute that is rigid and of

adequate size. for further details, please read the section entitled "claims

and returns" on page 7 of this manual.

Conditioning the Sensor

1. turn on the free radical analyzer.

2. Set the poise voltage on the free radical analyzer to +600mV.

3. Plug the IGS100 glucose sensor into the microsensor cable (WPI

#91580) and plug the other end into the free radical analzyer.

4. Immerse the sensor element into a 5mM glucose solution with 0.05M

PbS buffer (ph=7.4). It takes about 3-4 hours to stabilize the first time.

preparing Solution for Calibration

Prepare a 2M glucose standard solution by dissolving 7.2g glucose into

20ml distilled water. let the solution stand overnight at room temperature

to allow equilibration of anomers. Store solution at 4ºc.

Calibrating the IGS100

1. condition the sensor as described above.

2. remove the sensor from the glucose solution. rinse the sensor with

distilled water.

3. Immerse the glucose sensor tip into 20ml of 0.05M PbS solution.

4. Place a magnetic stirring bar into the solution. turn on the stirrer so that

the bar is stirring at a moderate rate.

NOTE: the rate of the stirrer should not be modified once it is set.

5. After waiting a few minutes for the current to stabilize, record its value.

typically the current should be a few nA or less. ( It should not exceed 20nA.)

NOTE: the calibration should be carried out at the temperature at which the measurement of glucose is to be made. this can be accomplished by placing the vial and stand in a water bath at the appropriate

World Precision Instruments

temperature, and allowing the temperature of the solution in the bottle

to equilibrate with water bath.

5. once the current has achieved a stable value, record this value or use

zero function in the instrument to set the baseline to zero.

6. Add 20µl of the 2M stock glucose solution into the 20ml of 0.05M PbS

buffer solution. the concentration of glucose in the solution is now 2mM. the current output will rapidly increase upon addition of glucose and reach a plateau in a couple minutes.

7. Add an additional 20µl aliquot of 2M stock glucose solution when the

signal reaches a plateau. the concentration of glucose in the solution is increasing by 2mM with the addition of each aliquot. When the current output reaches a plateau, record the value displayed on the free radical analyzer.

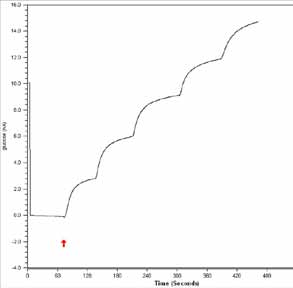

8. repeat step 7 another three times. A typical calibration plot looks

similar to the one shown in Fig. 3.

Fig. 3–Calibration plot showing five aliquots of 2M glucose injected into PBS solution

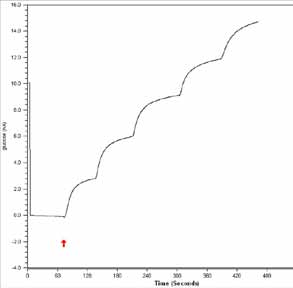

9. Plot the current readings against the total glucose concentration on

a graph. the slope of this line indicates the sensitivity of the glucose

sensor. once the sensitivity of the glucose sensor is known, the sensor is ready for experimental use.

World Precision Instruments

Fig. 4–Calibration data plotted shows the linear rise in current with the increase of

the solution molarity

NOTE: Since the enzyme is consumed as the sensor is used, the sensor should be re-calibrated before each experiment.

SeNSOR CARe ANd MAINTeNANCe

Storing the Sensor

STANDBY: If the sensor is being used the next day, it should be stored with

the tip suspended in 5mM glucose solution at 4ºc.

LONG-TERM: for long-term storage of more than one week, rinse the sensor tip with distilled water and let it dry. Protect the tip and store the sensor dry at 4ºc. It is best to store the sensor in its original box with the tip suspended.

Maintaining the Sensor

After each use, rinse the sensor with distilled water.

Sterilizing the Sensor

the sensor can be sterilized chemically using an appropriate disinfectant

(for example, cidex, WPI#7364).

CAUTION: do not use alcohol on the sensor.

World Precision Instruments

ACCeSSORIeS

Table 1: Accessories

Microsensor cable

If you have a problem/issue with your IGS100 sensor, contact the WPI technical Support team at 941.371.1003 or [email protected].

the IGS100 sensor conforms to the following specifications:In Vitro Precision

coefficient of variation (cV) ≤5%

36 - 450mg/dl (or 2-25mM)

Interference Species

Acetaminophen, ascorbic acid, uric acid

diameter: 0.6 mm

Active sensor length: 1.5 mm

reference electrode

Ag/Agcl integral

Polarization Voltage

3-4 months in solutions at room

temperature under continuous polarization; 15-30 days in vivo.

operating conditions

20°–40° c (68°–104° f)

Storage conditions

4°–25° c (50°–77° f)

World Precision Instruments

WARRANTy

WPI (World Precision Instruments, Inc.) warrants to the original purchaser that this equipment, includ-

ing its components and parts, shall be free from defects in material and workmanship for a period of

30 days* from the date of receipt. WPI's obligation under this warranty shall be limited to repair or re-

placement, at WPI's option, of the equipment or defective components or parts upon receipt thereof

f.o.b. WPI, Sarasota, florida u.S.A. return of a repaired instrument shall be f.o.b. Sarasota.

the above warranty is contingent upon normal usage and does not cover products which have been modified without WPI's approval or which have been subjected to unusual physical or electrical stress or on which the original identification marks have been removed or altered. the above warranty will not apply if adjustment, repair or parts replacement is required because of accident, neglect, misuse, failure of electric power, air conditioning, humidity control, or causes other than normal and ordinary usage.

to the extent that any of its equipment is furnished by a manufacturer other than WPI, the foregoing warranty shall be applicable only to the extent of the warranty furnished by such other manufacturer. this warranty will not apply to appearance terms, such as knobs, handles, dials or the like.

WPI makes no warranty of any kind, express or implied or statutory, including without limitation any warranties of merchantability and/or fitness for a particular purpose. WPI shall not be liable for any damages, whether direct, indirect, special or consequential arising from a failure of this product to operate in the manner desired by the user. WPI shall not be liable for any damage to data or property that may be caused directly or indirectly by use of this product.

Claims and Returns

Inspect all shipments upon receipt. Missing cartons or obvious damage to cartons should be noted on the delivery receipt before signing. concealed loss or damage should be reported at once to the carrier and an inspection requested. All claims for shortage or damage must be made within ten (10) days after receipt of shipment. claims for lost shipments must be made within thirty (30) days of receipt of invoice or other notification of shipment. Please save damaged or pilfered cartons until claim is settled. In some instances, photographic documentation may be required. Some items are time-sensitive; WPI assumes no extended warranty or any liability for use beyond the date specified on the containerdo not return any goods to us without obtaining prior approval and instructions from our returns department. goods returned (unauthorized) by collect freight may be refused. goods accepted for restocking will be exchanged or credited to your WPI account. goods returned which were ordered by customers in error are subject to a 25% restocking charge. equipment which was built as a special order cannot be returned.

contact our customer Service department for assistance in the repair of apparatus. do not return goods until instructions have been received. returned items must be securely packed to prevent fur-ther damage in transit. the customer is responsible for paying shipping expenses, including adequate insurance on all items returned for repairs. Identification of the item(s) by model number, name, as well as complete description of the difficulties experienced should be written on the repair purchase order and on a tag attached to the item.

* Electrodes, batteries and other consumable parts are warranted for 30 days only from the date on which the customer receives these items.

World Precision Instruments

World Precision Instruments, Inc.

International Trade Center, 175 Sarasota Center Blvd., Sarasota FL 34240-9258

Tel: 941-371-1003 • Fax: 941-377-5428 • E-mail: [email protected]

Astonbury Farm Business Centre • Aston, Stevenage, Hertfordshire SG2 7EG

Tel: 01438-880025 • Fax: 01438-880026 • E-mail: [email protected]

Zossener Str. 55, 10961 Berlin

Tel: 030-6188845 • Fax: 030-6188670 • E-mail: [email protected]

Physio-Tech Co., Ltd.

1-6-3 Iwamoto-cho, Chiyoda-ku, Tokyo 100-0032

Tel: 81-3-3864-2781 • Fax: 81-3-3864-2787 • E-mail: [email protected]

Coherent Life Sciences Pty. Ltd.

116 Sir Donald Bradman Dr • Hilton, South Australia 5033

Tel: (03) 9887-6262 • Fax: (03) 9887-9585 • E-mail: [email protected]

China & hong Kong

WPI Shanghai Trading Co., Ltd.

Rm 20a, No8 Dong Fang Rd., Lu Jia Zui Financial District, Shanghai PRC

Tel: +86 688 85517 • E-mail:[email protected]

Source: http://www.wpiinc.cn/uploads/soft/151216/IGS100_IMs.pdf

TEMPLE UNIVERSITY Office of the Vice Provost for Research Division of Research Compliance Institutional Biosafety Committee Standard Operating Procedure (SOP) - Tamoxifen Principal Investigator: _ Room & Building #: _ Department: Phone # Date: _ Location(s) Covered by this SOP. Building Lab # Fume hood area Animal procedure Animal Holding

Bulletin of Environment, Pharmacology and Life Sciences Bull. Env. Pharmacol. Life Sci., Vol 5 [6] May 2016: 48-52 ©Academy for Environment and Life Sciences, India Online ISSN 2277-1808 Journal's URL:http://www.bepls.com CODEN: BEPLAD Global Impact Factor 0.533 Universal Impact Factor 0.9804 ORIGINAL ARTICLE OPEN ACCESS