Levitra enthält Vardenafil, das eine kürzere Wirkdauer als Tadalafil hat, dafür aber schnell einsetzt. Männer, die diskret bestellen möchten, suchen häufig nach levitra kaufen ohne rezept. Dabei spielt die rechtliche Lage in der Schweiz eine wichtige Rolle.

Catalog lv 71 en, chapter

Welcome to Automation and Drives

Low-voltage switchgear –

the basis for progressive solutions

Totally Integrated Automation –

innovations for more productivity

Totally Integrated Power –

energy distribution and management

from one source

SIVACON 8PS –

Busbar Trunking Systems in Action

SIVACON 8PS –

Engineering Tools for precisely

dimensioned, economical solutions

Siemens LV 71 · 2004/2005

Welcome to

Automation and Drives

We would like to welcome you to Automationand Drives and our comprehensive range ofproducts, systems, solutions and services forproduction and process automation andbuilding technology worldwide.

With Totally Integrated Automation andTotally Integrated Power, we deliver solutionplatforms based on standards that offer youa considerable savings potential.

Discover the world of our technology now. Ifyou need more detailed information, pleasecontact one of your regional Siemenspartners.

They will be glad to assist you.

Low-voltage switchgear and controlgear –

the basis for progressive solutions

Everyday life would be unimaginable without electric power. Competence and innovations in switching and electrical installation technology are prerequisites so that power can be used without danger and user-friendly in industrial facilities and buildings. We have been providing you with these prerequisites for more than 110 years and are permanently de-veloping new features – innovations which permit you to use power more safely and eco-nomically.

Low-voltage switchgear from Siemens offers a comprehensive and innovative range of products covering switching devices for load feeders or the distribution of power, control and signaling devices as well as complete cabinet systems. Multi-functional, uniform con-cepts such as Totally Integrated Power, Safety Integrated or ECOFAST additionally permit our product portfolio to be combined into optimized systems.

All in all, we can provide you with innovative components for switching and electrical in-stallation technology which utilize state-of-the-art features such as integration and com-munication as the basis for advanced and uniform solutions which provide you with many benefits.

Totally Integrated Automation

innovations for more productivity

With the launch of Totally Integrated Automation in 1996, we

were the first ones on the market to consistently implement

the trend from equipment to an integrated automation

solution, and have continuously improved the system ever

Whether your industry is process- and production-oriented or

a hybrid, Totally Integrated Automation is a unique "common

solution" platform that covers all the sectors.

Totally Integrated Automation is an integrated platform for the

SIMATIC NET

ECOFAST IP65

entire production line - from receiving to technical processing

and production areas to shipping. Thanks to the system-oriented

engineering environment, integrated, open communications

as well as intelligent diagnostics options, your plant now

benefits in every phase of the life cycle.

In fact, to this day we are the only company worldwide that

can offer a control system based on an integrated platform

for both the production and process industry.

SIMATIC IT Framework

SIMATIC HMI

SIMATIC PCS 7

PROFIBUS PA

and Control

Totally Integrated Power

energy distribution and management

from one source

Totally Integrated Power by Siemens offers integrated

solutions for energy distribution in functional and industrial

buildings covering everything from medium-high voltage to

power outlets.

Totally Integrated Power is based on integration in

planning and configuration as well as coordinated products

and systems. In addition, it features communications and

software modules for connecting power distribution systems

to industrial automation and building automation, thereby

offering a substantial savings potential.

PROCESS FIELD BUS

Products and systems

£ 110 kV

Planning and configuration

Cost center

EMPLOYEECOST CENTER

PAY PERIOD BEGINNINGPAY PERIOD ENDING

Air conditioning system

central ON

Replacing circuit

instabus EIB

SIVACON 8PS –

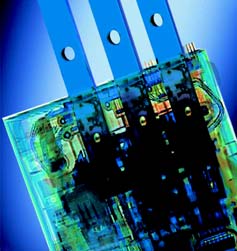

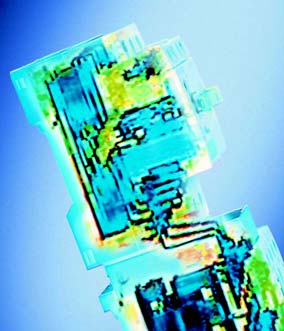

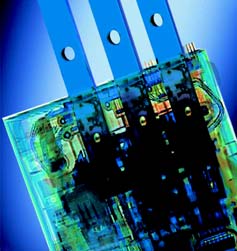

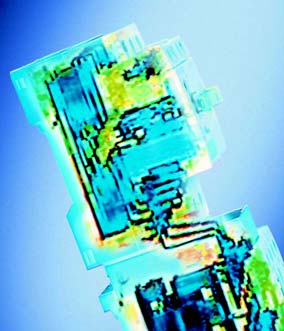

Busbar Trunking Systems in Action

Busbar trunking systems in the low-voltge range perform the safe and reliable transmission and distribution of electrical power from transformer via main distribution board and sub-distribution board right to the load. Siemens busbar trunking systems are the complete and efficient answer in this area:• The CD system

• The BD01 system

for 40 A to 160 A

• The BD2 system

for 160 A to 1250 A

The BD 01 system is quick to install and ideally suited for use in workshops and

• The PEC system

for 800 A to 6000 A

trade premises, as here, at a photo-

• The LD system

for 1100 A to 5000 A

• The LX system

for 800 A to 6300 A

Alle these systems are 'Type-tested LV switch-gear assemblies' (TTA) to IEC 60 439-1 and -2. This ensures that they offer a standard of safety and reliability that meets the particularly high performance expectations of automated pro-duction and for building services provision.

Performance characteristics:• Clear network structure• Unproblematic retrofitting in the event of load

• Low operating costs due to uninterrupted ser-

• Simple planning and installation

The ideal system for production lines needing a great deal of power is the LD system up to 5000 A.

Room-covering systems for lighting installa-

tions and small loads

The CD system (up to 40 A) allows you to supply

lighting installations covering the whole expan-

se of, say, furniture showrooms, supermarkets

or greenhouses with power, and also provides

the means to easily fix them in position.

Due to its pleasing appearance, the equipment

is well suited for use in sales rooms visited by

the public. On the other hand, its high degree of

protection, to IP54, allows the CD system to be

used even in harsh environments.

The power source for loads with no fixed

location

The BD01 system is ideally suited for the power

supply (up to 160 A) in workshops and trade

premises. The trunking units are easy and quick

to put together. The anti-rotation feature on the

tap-off units makes sure that the units are

correctly fitted and allows for easy retrofitting

even while the production is running.

Other benefits: minimum stock holding and un-

In the petrochemical industry, it is the PEC system that provides reliable and fault-free power supply.

complicated planning due to one standard frame size for five different current ratings.

Universal power distribution

The BD2 system (up to 1250 A) can supply

power to medium-size loads in buildings and in

all industrial applications. Prefabricated tap-off

units fitted with many differing component

combinations make this equipment universally

applicable. Two standard frame sizes covering

all current ratings simplify stock keeping and

planning.

Safe and reliable power transmission in the

petrochemical industry

The PEC resin-insulated system, up to 6000 A,

has a high degree of insulation protection and

thus an enormous resistance to external interfe-

rence factors. This ensures safe and reliable

transport of power even in rough weather or in

highly dust and dirt and corrosion polluted

industrial environments. Typical applications of

this system is the petrochemical industry, waste

incinerators and power stations.

Siemens offers modular component cabinets for indication, control and monitoring of the flow of power through busbar trunking systems. These cabinets are equipped with bus

High system serviceability in production

interfaces, control circuit devices and power meters.

The louvred LD busbar trunking system, up to 5000 A, is the system for transporting current in production lines with a large energy require-ment, such as in the automotive industry. A separate PE busbar ensures that the protective device in such a system responds reliably even if the current paths are relatively long. The high short-circuit rating allows medium-voltage switches to be used as protective elements for the transmission of power between transformer and main circuit-breaker. Tap-off units up to 1250 A available as standard.

Flexible power distribution in multi-storey

buildings

The LX sandwich-style system, up to 6300 A, is

used where large quantities of power need to be

transported, uninfluenced by the mounting posi-

tion of the system.

Conductor configurations with the PE conductor

insulated along its entire length, and a double-

size neutral can ensure the interference-free dis-

The LX busbar trunking system is the perfect equipment for multi-storey buildings where large quantities of power need to be transpor-

tribution of power in places such as radio

ted, uninfluenced by the mounting position of the system.

stations, computer centres or at internet providers'. The system is protected to IP54 as standard, and tap-off units up to 1250 A availa-ble as standard.

SIVACON 8PS - Engineering Tools for

precisely dimensioned, economical solutions

Engineering tools from Siemens help generate precisely dimensioned and economical plan-ning and design solutions, even for complex ap-plications.

MatSelect

Using MatSelect, product and material data can

be administered with self designed or

standardised classification systems. It has inter-

faces to Eldanorm, Datanorm, ASCII format and

ProPlan.

NetPlan

Planning software for power flow, short-circuit

calculation and device dimensioning with selec-

tivity analysis and protective against electric

shock of low-voltage networks, available in

English, German, French and Italian.

NetPlan enables you to graphically represent the network and to

Selection software for protective switches to en-

calculate the load flow and the prospective one-pole to all-pole short

able star networks to be correctly dimensioned;

available in several languages.

BusbarSelect

Selection aid for generating quotations, invitati-

ons to tender and orders for busbar trunking

systems up to 1250 A; available in several

languages.

Quotation texts

Prepared texts (in German) for generating

customer specifications in the formats: Architext

excellent, GAEB 81 and Word 97.

Should you have any queries concerning instal-lation, functionality or application options – please mail us [email protected] will be pleased to assist you.

In BusbarSelect, you select the trunking units for your system from a menu, and then transfer them into an order or quotation list.

Busbar Trunking Systems,

Overview

Siemens LV 71 · 2004/2005

Busbar Trunking Systems, Overview

Technical Overview

Busbar trunking systems

Rated operational

active conductors

IP54 with accessories, IP55 on request

LDA1 – LDA8

LDC2 – LDC8

LXA01 – LXA10

LXC01 – LXC10

IP55 with accessories

Siemens LV 71 · 2004/2005

Busbar Trunking Systems, Overview

every 0.5 or 1 m

Can be combined with networkable

tap-off units for lighting control sys-

painted sheet steel housing

Al or Cu busbars,

Can be combined with networkable

(without tap-off

tap-off units for lighting control sys-

tems, remote switching and load mon-

Information about the LD and

Al or Cu busbars,

(without tap-off

LX systems: from your

Siemens sales outlet.

Can be combined with networkable tap-off units for remote switching and load monitoring

Al or Cu busbars,

(without tap-off

Siemens LV 71 · 2004/2005

Busbar Trunking Systems, Overview

System Overview

Siemens LV 71 · 2004/2005

Busbar Trunking Systems, Overview

Up to 6300 A

CD system

LX system

Reduced planning costs by simplified engineering

The busbar trunking system for power transmission and distribution in

Quick-release plug-in connection for fast assembly

Tap-off points on both sides for optimized utilization of the busbar

Detailed information about this system is available from your Siemens sales outlet.

Even electrical loading of the CD system conductors achieved by connect-ing an equal number of tap-off plugs to each individual phaseVersatility through high degree of protection to IP54 of the standard

PEC system

The busbar trunking system for power transmission under extreme environ-

Tap-off plugs allow fast, flexible load relocation (even on live sytems).

mental conditions (IÜP68).

Detailed information about this system is available from your Siemens sales outlet.

Up to 160 A

Networkable busbar trunking system

BD01 system

Networkable function expansions for combination with known tap-off

Flexible power supply

Junction units for changes in direction

Quick, straightforward planning

– large area lighting control systems– remote switching and signalling in industrial applications

Time-saving assembly

– load monitoring of decentral power tap-offs

Reliable mechanical and electrical connections

EIB, AS-i and PROFIBUS bus systems

High level of stability, low weight

Quick, straightforward planning

Positive opening and closing of tap-off points

Flexible with expansion and modification

Versatile tap-off units

Few basic elements

Can be retrofitted to existing installations

Modular system reduces stock-holding

Simple contact establishment of bus line with insulation displacement

High degree of protection to IP54 with tap-off points at sides and bottom

connection feature

for extreme ambient conditions, otherwise IP50.

Can be used with the BD01, BD2, LD, and LX systems

Up to 1250 A

BD2 system

Design software for busbar trunking systems up to 1250 A

Quick, straightforward planning

This CD-ROM is available free of charge from your Siemens sales outlet.

Time-saving, cost-efficient assemblyReliable, safe operationFlexible modular system with simple solutions for every application

Early planning of power distribution possible without precise knowledge of

consumer locations

Fast operational readiness through quick, easy assembly

High degree of protection to IP54 for use in harsh industrial environments

Busbar trunking systems BD2A/BD2C and LDA/LDC from 160 A to 5000 A

Innovative construction:

No compensating units for expansion compensation required.

Planning guideSIVACON 8PS

Busbar trunking systems LXA/LXC over 800 A

These planning aids are available from your Siemens sales outlet.

Up to 5000 A

LD system

The busbar trunking system for optimized power distribution in industry.

Reliable, safe operation

Time-saving, cost-efficient assembly

Safe and flexible power distribution up to 6300 A

Space-saving compact construction type up to 5000 A in an enclosurePlug-in tap-off units up to 1250 AType-tested connection to service distribution boards and transformers

Siemens LV 71 · 2004/2005

Busbar Trunking Systems, Overview

Notes

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Examples

Engineering of vertical busbar runs

Degree of protection

Vertical runs may be designed to degree of protection

IP34 or IP54.

The type suffix L+LD-L120.-X.(Y.) is used for LDA and LDC systems. The centre of the fire barrier is always the centre of the fire ceiling thickness �.

For LDA 8 and LDC 8 systems, the length of the outer fire barrier is 0.68 m (otherwise 0.48 m).

Where possible, the fire barrier should be provided on standard trunking units.

For straight trunking units for vertical installation with-out any tap-off point(s), the closest fire barrier position is at X = 1.10 m due to the position of the expansion com-

For straight trunking units for vertical installation with a tap-off point AD 1,4, the closest fire barrier position is at X = 2.05 m (X = 1.95 m for LDA(C) 8).

For trunking units with a tap-off point AD 1,8, the closest fire barrier position is at X = 2.45 m (X = 2.35 m for LDA(C) 8)

The hooks must always point downwards with the hook opening pointing towards the wall �.

There should be a clearance of at least 0.48 m (LDA(C) 8 = 0.58 m) from the centre of the ceiling to the bolt end �.

The fixing elements must be fitted about 0.45 m below the ceiling �.

At least one pair of fixing brackets is required per trunk-

The adjustment capability of � 50 mm allows wall unevenness to be compensated for �.

The wall clearance with the LD busbar system when using vertical fixing brackets is at least 20 mm �.

When engineering tap-off points, trunking units for vertical engineering with integrated expansion and an integrated fixed point must always be used .

� Centre of fire barrier is always the centre of the fire ceiling.

� Hook always downwards with hook opening pointing

towards the wall.

� Minimum distance between the centre of the ceiling and the

bolt end: 0.48 m (LDA(C) 8 = 0.58 m).

� Fixing element clearance.

� At least one pair of fixing brackets is required per trunking

� Wall unevenness is compensated for by ± 50 mm adjustment

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering of trunking unit lengths

• Height of storeys up to 3.2 m

– The trunking unit length is equal to the height of

• Heights of storeys greater than 3.2 m

– Trunking units with standard limb lengths should be

– A vertical trunking unit can be combined with a

maximum of one standard trunking unit.

The following table should be used only as a rough guide for engineering design purposes.

Trunking unit for

Trunking unit for

Height of ceiling 2.75 m, Ie = 1100 A

Degree of protection IP34, 4-conductor system, with fire barrier, tap-off point at X = 1.4 m

Selected trunking unit: LDA 1423-V-1W2,75-AD1,4 +LD-L120A-X2,27.

Straight trunking units with tap-off point(s) must always be trunking units for vertical installation.

Height of ceiling 4.80 m, Ie = 2400 A

Degree of protection IP54, 5-conductor system, without fire barrier

Selected trunking units: LDA 7615-V-3W3,2, LDA 7615-1,6.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Examples

• Number and height of the storeys

• Ratings per storey and types of load• Utilization and rated load factors• Feed transformers (characteristic data, position)• Special requirements (degree of protection, fire barrier

• Number and size of the height adjustments (> 1.3 m)

• Number of coded tap-off points required.

• 11 storeys each with 8 residential units• Rating 38 kW per residential unit• Ue = 400 V, p. f. = 0.8, 5-conductor system,

degree of protection IP54

• Rated load/utilization factor: α = 0.7, β = 0.45• Feed from the distribution board via LD connection

• Transformer rating = 1600 kVA• Details and construction plans required for engineer-

• Tap-off units to be positioned at eye level.

The rated current per storey is calculated using the fol-

lowing formula. The formula also allows the rated cur-rent for the tap-off units to be defined.

= --------------------- × 10

3 × U × cosϕ

= Rated current per storey (A)

= Rated operational voltage (V)

Pinst = Total installed power per storey (kW)cos ϕ = Power factor (p. f.)

= Rated load factor

1) If � is not stated, the values from the "Number of main cir-

cuits" table may be used. If the p. f. is not stated, this may be assumed to be = 1 for purely domestic high-rise buildings.

= --------------------- ×

For item numbers refer to the parts list for the engineering example

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

The rated current per busbar run is calculated from:

Unless the application necessitates a change, the rated load factor from EN 60439 may be used for α.

Number of main circuit

= Rated current (A)

β2) = Utilization factor for the total number loads

2) The local PESs have good empirical values for utilization

6 to 9, inclusive

factors; these differ between regions. Average values are given in the "Type of Load" table.

Notes relating to the engineering example

Since the rated current for IP54 vertical is the same as for

LDA 6515 is chosen here since IB is reduced from 3100 to

horizontal systems, the complete run may be engineered

2000 A because of the degree of enclosure protection

using LDA 6615.

Average values are always quoted for the utilization fac-

Once the system has been selected, the following docu-

ments are produced for the order:• Installation plan using the LD engineering tool

Types of load

Dwellings with electric cookers and

• Parts list generation using the LD engineering tool

(for about 100 connections)

• Binding order

Off-peak storage heaters

Lighting in office buildings and in

buildings for commercial use

Lifts and general installations

Parts list relating to the engineering example

Max. rated current

Distribution board connection units for LD

connection to ID 2000

Straight trunking unit (optional length with

LDA 6615-LVR-Y1,13

Offset elbow with longer Y-leg and fire

LDA 6615-K-V-2,4-AD1,4

Straight trunking unit for vertical installation

with one tap-off point

Straight trunking length (optional length)

with fire barrier

End flange with hook

Tap-off unit with fuse switch-disconnector

Fixing bracket for vertical installation

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Tap-offs

Tap-off units

All tap-off units have the following common features:• Galvanized steel enclosure with paint finish• Handles for fitting, removing or transporting the tap-

• Door or removable cover• Guide and fixing elements for mounting on busbar

• Contact protection for fitting/removing

Safety during handling

Early-make PE or PEN

Tap-off with early-make and late-break PE or PEN con-ductor contact when fitting or removing the tap-off unit. In the 5-conductor system, the PE connection is made via sliding contacts on the coding brackets. In the 4-conduc-tor system, this is provided by a longer PEN bar on the contact apparatus.

A 7-conductor system (N/PEN = ½ L) is shown by way of example below.

4-conductor (TN-C system)

5-conductor (TN-S system)

� Coding brackets

A specified sequence of operations ensures that no load

The LDA(C) system enables tap-off units to be fitted and

current can flow when fitting or removing the tap-off

removed whilst the entire LD system is still energized.

All live parts are finger-proof during fitting and removal (IP20).

Correct orientation and installation

The tap-off units should only be opened when the pro-

Coding brackets on the tap-off unit and on the tap-off

tective device is open, i.e. switched off.

point of the trunking unit (key-lock principle) prevent the tap-off units from being fitted incorrectly on the tap-off

All live internal live parts are finger-proof.

This prevents the tap-off unit from being fitted in the opposite way round on tap-off point and ensures the cor-rect allocation of 4- and 5-pole LD systems.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Relationship between the hook opening (phase sequence) and the tap-off unit cable entry

With the tap-off "above"=-AD, the cable entry is from the hook end.

LD.-K-AD� Cable entry at the end� Cable entry at the side

With the tap-off "below"=-ADU, the cable entry is from

Illustration of a coding bracket in a 4-pole system

the bolt end.

LD.-K-ADU� Cable entry at the end� Cable entry at the side

When tap-off units are mounted on straight trunking units for vertical installation (-V-AD), cable entry is from the hook end.

Illustration of a coding bracket in a 5-pole system

Protection against direct contact

Degree of protection IP20 is provided at the open tap-off point on the trunking unit and on the contact system of the tap-off unit.

Cable connection safety feature

A plate which separates the cable connection area from the component mounting area within the tap-off unit

prevents cables being inserted from touching live parts.

LD.-K-V-AD� Cable entry at the end� Cable entry at the side

Trunking units for vertical installation must always be used when engineering tap-off points for vertical use and with adjustments in height >1.3 m.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Tap-offs

Tap-off units GSTA fuse switch-disconnectors

Degree of protection

The compact design means that one size covers all cur-

Degree of protection IP 30 is standard. The high degree

rent ratings.

of protection IP 54 (type suffix) can be provided just by fitting an additional cover either at the factory or directly

The rated currents extend from 125 A to 630 A; and 1 × GSTA 00 or 2 × GSTA 00 may be selected for the 125 A version.

Safety during fitting/removal while the system is live is achieved by a specified fitting/removal sequence, see the relevant intallation instruction, and by subsequent open-ing of the cable connection area after releasing 2 fixing screws. The cover cannot be removed until the top sec-tion of the fuse switch-disconnector has been removed.

Degree of protection IP30

Degree of protection IP54

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Cabling box and cable entry

Tap-off units with GSTZ fuse switch-disconnectors

• The bolt connection is designed for cables up to

• The standard tap-off unit version has an end cable

There is one size of the tap-off unit. It can accommodate both, GSTZ 2 or GSTZ 3.

• Where side cable entry is required, a cabling box (type

suffix) can be flange connected at the factory or directly on site.

Cable entry at the end

The rated currents are 400 A and 630 A, respectively.

Safety by design

The fixed procedure for fitting/removal of the tap-off unit provides protection against mishandling.

Degree of protection

Degree of protection IP30 without door is standard. The high degree of protection IP54 can be achieved by fitting a door (type suffix).

Cable entry at the side

Door hinging

A cable entry plate for a maximum of 3 multi-core cables

The doors may either be supplied with "door hinged on

up to 300 mm2 is standard. The cables are supported by

the left" or "door hinged on the right". When ordering,

an integral cable anchoring rail in the tap-off unit

the type suffix +LD-TL. or +LD-TR. must be used for this

(bracket clamps to be supplied on site). An undrilled alu-

minium entry plate for customized fitting with cable glands on site, for single core cable entry can be obtained

The door hinging may be converted on site.

by stating the relvant type suffix.

The bolt connection is designed for cables up to 300 mm2.

Sealing for the NH fuse switch-disconnector sizes NH 00

The standard version is available with end or side cable

and NH 01 is standard. (Sealing for sizes NH 2 and NH 3

on request).

For multi-core cables, the split cable entry flange is designed for a maximum of 2 multi-core cables up to 300 mm2.

For single-core cables, the cables are inserted through a drilled aluminium plate with PG cable glands. The num-ber and size of the glands may be found in the Technical Data section.

The cables are held by a cable anchoring rail within the tap-off unit.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Tap-offs

Tap-off units with circuit-breakers

• High switching capacity (H) for size 1 (80 . 250 A)

• 2 sizes depending on the circuit-breaker in use:

and 2 (400 . 570 A)

– Size 1 for tap-off units with NZM 7 circuit-breaker

• Very high switching capacity (S for size 3 (800 A)1))

• Circuit-breaker with 3 or 4-pole versions

– Size 2 for tap-off units with NZM 10 circuit-breaker

• 4-pole circuit-breakers (TN-S system) are fitted with

– 100 % releases for 80 . 250 A (NZM 7)

– Size 3 for tap-off units with NZM 14 circuit-breaker

– 60 % releases for 400 . 570 A (NZM 10)

– 0 % releases for 800 A1) (NZM 14)

• The circuit-breakers are fitted with NHI and RHI

standard and trip-indicating auxiliary contacts as standard. A shunt or undervoltage release can be selected for the version with remote operator.

• All control connections are wired to terminals.

NEW: Standard tap-off units with Siemens circuit-breakers. They will be published in the next catalog version (2005), as product development and tests have not yet been completed. For preliminary solutions, please contact your product managers.

Rated currents and switching capacity

Rated current Ie

Setting range of

Icu (kA)

Icu (kA)

(tap-off unit)

overcurrent

Ue = 400 V

Ue = 690 V

Tap-off-unit size 1, 80 . 250 A

NZM 7 circuit-breaker, H version (high capacity)

NZM 7 circuit-breaker, H version (high capacity)

NZM 7 circuit-breaker, H version (high capacity)

NZM 7 circuit-breaker, H version (high capacity)

NZM 7 circuit-breaker, H version (high capacity)

NZM 7 circuit-breaker, H version (high capacity)

Tap-off-unit size 2, 400 . 570 A

NZM 10 circuit-breaker, H version (high capacity)

NZM 10 circuit-breaker, H version (high capacity)

Tap-off-unit size 3, 800 A1)

NZM 14 circuit-breaker, S version (high capacity)

1) The rated current is dependent on the installation orientation

of the circuit breaker. With suspended installation of the tap-off unit (tap-off point at bottom), a rated current reduction to Ie = 720 A must be considered.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Safety during fitting

Tap-off units with circuit-breakers and motor drives

• A specified sequence of operations ensures that no

load current can flow when fitting or removing the tap-off units

Degree of protection

• All tap-off units with circuit-breakers have degree of

protection IP54.

• Terminal bolt for power cables connected between the

load and the circuit-breaker

• In the event of the circuit-breaker tripping or a tap-off

unit being opened, internal area protected to IP20 (finger proof)

• All tap-off units are provided with a cable entry for

• The tap-off unit is fitted with a remote operator (with-

multi-core and single-core cables. Entry is from the side

out handle) as standard. The circuit-breaker can be

and both cable entry plates can be exchanged (with

operated from the outside via a cover flap (ON/OFF).

each other) as required. A divisible cable entry plate is

The external actuating voltage of the motor operator

available for use with multi-core cables. This allows

spans the 220 . 240 V AC range. Tap-off units with

cables to be inserted easily from the top. An undrilled

NZM 14 span the 200 . 230 V AC range.

aluminium plate is available for single-core cables.

• All circuit-breakers are fitted with NHI and RHI stan-

dard and trip-indicating auxiliary contacts for ON, OFF and TRIPPED as standard. Potential-free contacts are

Tap-off units with circuit-breakers and handles

connected to the terminals.

The following table provides an overview:

400 . 570 A

1) The rated current is dependent on the installation orientation

of the circuit breaker (see HPL). With suspended installation of the tap-off unit (tap-off point at bottom), a rated current reduction to Ie = 720 A must be taken into consideration.

• Either an undervoltage release (non-delayed) or a

• The tap-off unit is fitted with a handle and cover inter-

shunt release can be used depending on the applica-

lock as standard. It can therefore only be opened when

tion at hand. These are wired to terminals. The exter-

the circuit-breaker is switched off.

nal voltage supply has a range as follows:– Size 1 and 2 have a supply voltage range for the

undervoltage release and shunt release of

• All circuit-breakers are fitted with NHI and RHI stan-

dard and trip-indicating auxiliary contacts as standard.

– Size 3 with shunt release 200 . 480 V AC

Potential-free contacts are connected to the terminals.

and with undervoltage release 200 . 240 V AC.

The following table provides an overview:

• All electrical connections for motor operator, auxiliary

contact and release are wired to a terminal and are connected (cable gland provided by customer) via a

cable entry knockout in the tap-off unit (1 x PG 29).

400 . 570 A

1) The rated current is dependent on the installation orientation

of the circuit breaker (see HPL). With suspended installation of the tap-off unit (tap-off point at bottom), a rated current reduction to Ie = 720 A must be taken into consideration.

NEW: Standard tap-off units with Siemens circuit-breakers. They will be published in the next catalog version (2005), as product development and tests have not yet been completed. For preliminary solutions, please contact your product managers.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Special cases

Reduction units

LD systems which pass through wall or ceiling apertures need a protective sleeve for mechanical protection, e. g.

against contamination by mortar.

Mounting and fitting notes

The protective sleeve can be fitted retrospectively.

It consists of a two-piece steel sleeve with a flange. The two L-shaped sleeve halves are screwed to one another

on the trunking unit. The protective sleeve is mounted on the trunking unit such that it can move.

For walls/ceilings which are thicker than 250 mm (= length of the protective sleeve), a second protective

Costs can be saved by reducing from 7/8/9-conductor to

sleeve may be used for extension

4/5-conductor LD systems for longer distances over which it can be demonstrated that the current load level is rela-tively low.

The voltage drop over longer distances must be taken into account.

3 Since the overall short-circuit rating of the complete run

is based on the smaller LD system, either the complete run must be limited to this value at the feeder or the short-circuit current must be limited to the lower value upstream of the reduction unit, e.g. by a coupling unit

� Protective sleeve, part 1

with a circuit-breaker.

� Protective sleeve, part 2

The smaller LD system must not be loaded with more than its permissible rated current.

The protective sleeve is not a substitute for the fire barrier.

Reduction units are equipped with a fixed point at the factory and are thus to be regarded as engineered fixed points.

With regard to the reduction to a busbar system with a lower rated current, the loop impedance must be calculated using the lowest prospective single-pole earth-fault current.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Parallel connection of LD runs

For economic reasons, it may be worthwhile to lay two runs with aluminium conductors instead of one LD busbar system with copper conductors.

Parallel connection of LD runs allows high currents to be carried. However, the voltage drop must be taken into account.

• Lighter mounting weight than when high currents are

transmitted via a single busbar run.

• The option of using the basic components for other

configurations, particularly in distribution installations which are modified frequently.

A lateral clearance of � 0.1 m is required between the parallel runs in order to allow the single-bolt clamp ter-minal to be tightenend, as well as a lateral clearance from the building structure and other obstructions of

When the fire barrier is used, the remaining space

between the busbar trunking systems in the wall/ceil-ing cutout must also be filled with fireproof mortar.

The runs should always be positioned along one another.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Special cases

Phase sequence reversal units

When carrying power over long distances using LDA(C) busbar trunking systems, a voltage drop of variable mag-nitude occurs. The voltage drop is caused by the arrange-ment of the conductors. The impedance values (details in the Technical data section) and the voltage drop resulting from them are determined as a mean value during type testing.

The use of three phase sequence reversal units achieve that the magnitude of the voltage drop in all three phases corresponds to this mean value. In practice, one phase sequence reversal unit is positioned after each third of the total length of the busbar run. Phase sequence reversal units are available on request.

Phase sequence reversal units are used where a low bal-anced voltage drop is to be achieved in a power transmis-sion system and where power is carried over long dis-tances at high load levels.

3 A phase sequence reversal unit is used for each third of

the total length of the busbar run. A total of three phase sequence reversal units is therefore required.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Transition from LDA(C).5 to LDA(C).6

Explanation of the type suffix +LD-B(H)5 +LD-B(H)5

• In a trunking run which uses reduction units, the loop

impedance must be calculated using the lowest pro-

• Upgrading existing installations using the old 5-con-

spective value of single-pole earth-fault current.

ductor version (PE = enclosure) to the new 5-conductor

• Implementation by type suffixes (+LD-B5; +LD-H5). The

system (PE conductor = separate busbar)

transitions should always be positioned in the straight

• Connecting ID2000 distribution boards (make Moeller)

trunking units. If the transition has to be in a junction

to trunking systems using the new 5-conductor system

unit or a distribution board connection unit, the mini-

• Connecting MODAN distribution boards (make

mum limb length must be 0.65 m.

Moeller) containing old LD connections.

• For this purpose, the first trunking unit in the new sys-

tem must be ordered with a type suffix.

The type suffix to be selected draws a distinction between two situations:

The hook of the new trunking unit is to be connected to the bolt of the old trunking unit.

1 ≠ 2LDA(C).5.-.

5-conductor system (PE = housing)

5-conductor system (PE = separate busbar)

The bolt of the new trunking unit is to be connected to the hook of the old trunking unit.

1 ≠ 2LDA(C).5.-.

5-conductor system (PE = enclosure)

5-conductor system (PE = separate busbar)

In a trunking run which uses reduction units, the loop

impedance must be calculated using the lowest pro-spective value of single-pole earth-fault current.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Special cases

Distribution board connection

LD connection to MODAN distribution boards

Connection to the new 5-conductor system LDA(C).6.

The LD connection in 5-conductor versions on MODAN

using a VEG and trunking unit

power distribution systems before 12/94 inclusive, is only possible with a LDA(C).6. junction unit to the LDA(C).5. system.

From 01.01.95, the first SOND versions manufactured with additional PE busbar in the MODAN were imple-mented, and adopted as the standard LD connection near

the end of 1996. To what extent a special junction is

required for this transitional phase must be clarified for each individual case with the respective specialist depart-ment in the MODAN product area.

LD connection to ID2000 distribution boards

(make Moeller)

In principle, the new 5-conductor version of the LD con-nection requires a reduction unit from LDA(C).6. to LDA(C).5. The minimum X length for the ID2000 distri-bution board connection unit is 0.65 m.

3 Connection to the new 5-conductor system LDA(C).-VE

The minimum X length for the ID2000 distribution board connection unit is 0.65 m.

Where the connection is made via a trunking unit with a reduction unit (in this case: LDA 5613-VEH-X0,65 +LD-B5), the loop impedance must be calculated using the lowest prospective value of single-pole earth-fault current.

For the ID2000 distribution board, the connection must use a half PEN/N

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Changing the connection configuration

for 7/8-conductor systems

Two busbar systems with differing L12 busbar position are to be connected.

Connections are available on request.

Connection is feasible only for the following busbar sys-tems:

5-conductor systems (old)

LDA 4413(5), LDA 5413(5),

LDA 4513(5), LDA 5513(5),

LDA 6413(5), LDA 7413(5),

LDA 6513(5), LDA 7513(5),

LDA 8413(5)

LDA 8513(5)

LDC 6413(5), LDC 7413(5),

LDC 6513(5), LDC 7513(5),

LDC 8413(5)

LDC 8513(5)

LDA 4423(5), LDA 5423(5),

LDA 4523(5), LDA 5523(5),

LDA 6423(5), LDA 7423(5),

LDA 6523(5), LDA 7523(5),

LDA 8423(5)

LDA 8523(5)

LDC 6423(5), LDC 7423(5),

LDC 6523(5), LDC 7523(5),

LDC 8423(5)

LDC 8523(5)

Connection is not feasible for 8/9-conductor systems with

an additional 5th conductor (LDA(C).6.).

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Special cases

Functional endurance class for busbar trunking systems

The functional endurance of our busbar trunking systems

has been tested in conjunction with the Promat Company

In Germany, the official certification of functional endur-

at the Braunschweig Materials Test Centre.

ance in the event of fire must be provided to DIN 4102

The tests cover all busbar trunking systems LD 1. to LD

8., LDC 2. and LDC 3. as well as LDC 6. to LDC 8. for

The verification documents are the test certificates

power transmission (busbar trunking systems without a

quoted for the respective items and the licences from the

tap-off point or tap-off unit).

Institut für Bautechnik Berlin [Institution for Construction

Owing to the official certification required, the fire bar-

Technology], issued to Promat GmbH, Postfach 101564,

rier material for our systems therefore may be obtained

D-40835 Ratingen.

only from the Promat Company.

In the course of harmonization, efforts are being made to

• Implementation may be carried out only by specialist

adopt the German Standards throughout Europe.

companies who have been instructed by the Promat Company.

• In addition to the marking of each trunking unit, the

installation company must provide a works certificate based on EN 10204, Section 2.1. Marking labels are

The following preconditions must be satisfied to achieve

available on request.

functional endurance. More detailed information may be

• The works certificate is used as verification of correct

obtained from the Promat Company.

design implementation. The works certificate may be

• Only Promatect-L 500 boards from the Promat Co. and

requested from the Promat Company, together with

specified fixing materials may be used for partitioning.

the documents required for correct installation.

The tests have been carried out only with these materi-

3 • Please refer to the responsible Promat specialist, for

als. The guarantee can be satisfied only by compliance

questions relating to design implementation details as

with this requirement.

well, since this documentation can provide only a

• The thickness d of the duct wall (see table next page)

rough outline.

depends on the busbar used and on the functional

• Further information is also contained in Promat Infor-

endurance class required.

mation Leaflets 490.15 and 660.30.

• The distance between suspension elements must not

exceed 1200 mm (see side view) and they must be

made of steel.

• Suspension elements must be dimensioned so that the

Postfach 10 15 64

calculated tensile stress is not greater than 6 N/mm2.

• The system must be gripped by a suspension element

Phone:+49 (21 02) 49 32 00

immediately in front of and behind the mineral fibre-

+49 (21 02) 49 31 11

board abutment points, unless it is supported directly

Contact: Dr. Wiedemann

below such points.

• Threaded rods must be fixed in the solid structure by

steel inserts (double installation depth, at least 60 mm,

For certain applications, DIN VDE 0108 requires that func-

maximum 500 N/insert) approved by the construction

tional endurance of busbar trunking systems for supply-

authorities, or by inserts officially certified to comply

ing power to parts of installations be provided for an

with the functional endurance class.

adequate time period, e. g. E 90 = fire resistance period 90 min.

• There should be no obstacles in the path of the trunk-

ing (straight run), and it must always be suspended

Fields of use with a high power requirement which are

from solid ceilings.

considered for use with LD busbar trunking systems with

• Every partitioned busbar system must be permanently

functional endurance are, for example, standby power

marked. The Promat marking labels must be fitted at

systems for supplying:

an easily visible point at intervals of 5 m (marking

• Passenger lifts with an evacuation circuit (E 30)

labels on request).

• Water pressure boosting systems for fire-extinguisher

water supplies (E 90)

For overview of the materials to be used, design of the

• Systems for dissipating smoke and heat in the event of

partitions and reduction of the rated current, see

Technical Information LV 71 T, pages 5/13 to 5/15.

• Fire-service lifts (E 90).

The main field of application extends to installations hav-ing a fire resistance period of 90 min.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Temperature response characteristic

The diagram shows how the rated current varies with the ambient temperature. This function applies to all LDA/LDC systems.

Ambient temperature ˚C (average over 24 hours)

Transition from the LD system (old)

to the LD system (new)

Rated current Ie [A]

Time period

No longer adaptable to the present-day systems

No longer adaptable

Adaptable according to IL (systems until the end of 1990, H/B 90 × 8)

1600 (2 × 90 × 6)

No longer adaptable to the present-day systems

Adaptable according to IL (systems until the end of 1990, H/B 90 × 8)

1600 (2 × 90 × 8)

Adaptable with LDA 4 according to Internal List

2000 (2 × 90 × 8)

(systems until the end of 1990, H/B 90 × 8)

1600 (2 × 90 × 8)

Adaptable according to IL (systems until the end of 1990, H/W 90 × 8)

Adaptable according to IL (systems until the end of 1990, H/W 90 × 8)

Adaptable to the present-day system

2500 (2 × 90 × 8)

Adaptable according to IL (systems until the end of 1990, H/W 90 × 8)

3100 (2 × 130 × 8)

Adaptable to the present-day system

3500 (2 × 130 × 8)

Adaptable according to IL (systems until the end of 1990, H/B 90 × 8)

Adaptable to the present-day system

2700 (2 × 90 × 8)

Adaptable according to IL (systems until the end of 1990, H/B 90 × 8)

3500 (2 × 130 × 8)

Adaptable to the present-day system, physically identical to LD6

1100 (90 × 8 × 0.575)

A special reduction unit (+LD-B5; +LD-H5) is required for connection of

LDA.5. (PE = enclosure) to LDA.6. (PE = separate conductor).

2000 (2 × 90 × 8 × 0.575) 1992 – to date

Important: the loop impedance must be calculated using the lowest

2500 (2 × 90 × 8)

prospective value of single-pole earth-fault current.

3000 (2 × 90 × 8)

3700 (2 × 130 × 8)

4000 (2 × 155 × 8)

A special reduction unit (+LD-B5; +LD-H5) is required for connection of

LDC.5. (PE = enclosure) to LDC.6. (PE = separate conductor).

3400 (2 × 90 × 8)

Important: the loop impedance must be calculated using the lowest

4400 (2 × 130 × 8)

prospective value of single-pole earth-fault current.

5000 (2 × 155 × 8)

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Distribution board connection to Moeller power distribution boards

Connection to MODAN distribution boards

Space required for connection

An LD connection may be made from above or below. The MODAN connection system is located entirely inside the distribution board.

In the versions with connection from above or below, the distribution board connection unit projects to a different extent into the distribution board, as the dimension

drawings show.

Special distribution board connection units with a metal rim LDA(C).-VEU-. are required for connection.

w = 500 – 3200

From Oct. 15th, 2004 onwards, all LDA(C).-VEU-. con-nection units are matched to SIVACON 8PV and 8PT distri-bution boards as a standard. The connecting depth from the outer edge of the enclosure to the fixing frame is modified to 121 mm (see dimension drawings).

To achieve the connecting depth of 68 mm, needed for MODAN distribution boards as shown in the drawings for connection from above and below, the VEU connection

units must be adapted with special MODAN accessories on site.

3 The connection units are available as straight, angled and

offset units. The positio of the connection system in the ditribution board must be considered. This has been turned by 90° in comparison to the older MODAN6000 power distribution system (manufactured until 04/2001)1).

During engineering, it must be remembered that the rated currents of the distribution boards are not necessar-ily the same as those of the chosen busbar system.

A special adapter is required for connecting the old 5-conductor LDA(C).5 (PE = enclosure) version of MODAN distribution boards to a new 5-conductor LDA(C).6 (PE = separate conductor) version of the LD system (see Engineering Section – Special Cases).

Connection to MODAN 6000 power distribution sys-tems up to 3200 A.

Connection from above

With MODAN 6000 power distribution systems

> 3200 A manufactured until 04/20021), the use of LDA(C). -2VEU.2) connection unit with a double Y-unit is required. For this purpose the LD connections are doubled and rotated by 90°.

Otherwise, the LD connection to the new MODAN power distribution system for rated currents up to 5000 A can be connected with a simple Y-unit.

1) The development and product release for the LD connection

> 3200 A of the MODAN manufactured after 04/2002 was only completed in 09/2003. For clarification of technical queries relating to the LD connection during the transition phase, please contact the respective specialist department in the MODAN product area.

2) Ask for LDA(C). -2VEU. as SOND variant.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Distribution board connection to Moeller power distribution boards

Dimensios of the top ond bottom plates for the LD connection

For busbar trunking system connection a

LD.1.; LD.2.; LD.3.; LD.4.;

LD.5. LD.6.; LD.7.; LD.8.;

LD.662.; LD.761.; LD.762.;

LD.861.; LD.862.

Dimensions of the top and bottom plates for the LD connection on a MODAN with a 4-pole IZMBG3 circuit-breaker

Connection from below� Front

For busbar trunking system connection a

� Depending on the conductor system the position of the PEN,

PE or L12 conductor on the MODAN connection is always on

LD.662.; LD.761.; LD.762.;

the rear side. On LD-VEU units, the bolt has been turned by

LD.861.; LD.862.

180° to allow front actuation of the bolt in the MODAN.

1) In order to ensure adequate ventilation, a minimum

clearance of 100 mm must be maintained. Smaller clearances on request. To allow the downstream trunking units to be connected, a minimum clearance of 180 mm (trunking unit height) must be maintained from the ground or the ceiling, depending on the hook/bolt position.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Engineering

Distribution board connection to Moeller power distribution boards

Connection to ID2000 distribution boards

Space required for connection

The connection is possible form above, below and from the rear.

The LD-connection system projects out of the distribution board from the top and the rear. For connection from

above or below, the connection system is rotated

through 90° compared to its position in a MODAN6000

distribution board.

The LD-connection is made using VEG+ normal trunking units or junction units. LDA(C) .-VEV(H) or LDA(C). -VE are used as trunking units when changes in direction are required.

Where connection is made from below, the LD connec-tion system is located entirely within the distribution board when (LDA(C).-VEU-.) distribution board con-nection units as for MODAN6000 are used.

The 4-conductor version is standard. Please refer to the "Engineering – Special Cases" section for the connection to a 5-conductor system.

Connection from above

3 Rated currents

The distribution board rated currents need not be the

Connection options exist with

same as those of the chosen busbar system.

• LD.41.-VE. (VE knee)

An LD connection using the new 5-conductor system

• LD.41.-VE. (VE knee, offset)

LDA(C).6 (PE conductor = separate busbar) to an

• LD.41.-VEG1(2) (distribution board connection flange)

ID2000 distribution board requires a trunking unit

+ trunking unit (straight, knee offset).

with +LD-B5 or +LD-H5 accessories. See the Engineer-

Example: Connection from above

ing – Special Cases section for further details.

The respective earth fault loop imepedence values of

the LDA(C).5 and LDA(C).6 LD systems must be taken into account.

Connection to LD busbar trunking systems of the old 5-conductor version LDA(C).5. (PE = enclosure) is avail-able on request.

During engineering design, consider that the LD bus-

bar trunking system LD.4. to LD.8. can only be con-

nected to the ID2000 point distribution board with

half PEN(N) (e.g. LDA4413)

A reduction from full PEN(N) to half PEN(N) within the LD-busbar run is not possible.

Customized special solution busbar trunking connec-tions to the ID 2000 are not intended and therefore

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Distribution board connection to Moeller power distribution boards

Connection from the rear

LD.-VEU-W (.L).

Connection options exist with• LD.41.-VE. (VE knee)• LD.41.-VE. (VE knee, offset)• LD-VEG 1(2) (distribution board connection flange) +

trunking unit (straight, knee offset

Connection from below

Example: Connection from the rear

1) Minimum clearance required for trunking unit installation:

dependent on the hook/bolt position

2) For connection of the 5-conductor version, see "Engineering –

Special Cases" section.

Connection options exist with• LD.41.-VEU-.W* (optional length)• LD.41.-VEU-L. (knee)

• LD.41.-VEU-L. (knee, offset).

Example: Connection from below

180 (237)

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Straight Trunking Units

LDA (C).-D-.

LDA (C).-V-.

LDA (C).-J-.

LDA (C) 1. to LDA (C) 3.

LDA (C) 1.-K-. to LDA (C) 3.-K-.

LDA (C) 4. bis LDA (C) 8.

LDA (C) 4.-K-. bis LDA (C) 8.-K-.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

AS transformer and distribution board connection pieces

External dimensions

LD.-AS 1 +LD-.

Lug intervals as supplied

3 × 150 – 1603)

Lug intervals which can be produced on site by rotating the connection lugs

3 × 165 – 1803)

Fixing materials:

• M12 × .-8.8 bolts

(not supplied as standard)

• Lock washers to DIN 6796-12-FSt (2 off per bolt)• Muttern M12-8 nuts

1) Reference dimensions for engineering = centre of AS 1 (362.5 mm).

For further details, see the Engineering - Incoming Connections Section.

2) Height dimensions apply to all LD connection units.

3) Lug intervals apply to cable copper busbar widths ≤ 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

AS transformer and distribution board connection pieces

External dimensions

LD.-AS 2 +LD-.

Lug intervals as supplied

3 × 190 – 2802)

Lug intervals which can be produced on site by rotating the connection lugs

3 × 285 – 3802)

Fixing materials:

• M12 × .-8.8 bolts

(not supplied as standard)

• Lock washers to DIN 6796-12-FSt (2 off per bolt)• Muttern M12-8 nuts

1) Reference dimensions for engineering = centre of AS 1 (542.5 mm).

For further details, see the Engineering - Incoming Connections Section.

2) Lug intervals apply to cable copper busbar widths ≤ 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

AS transformer and distribution board connection pieces

External dimensions

LD.-AS 3 +LD-.E (+LD-.G)

Lug intervals as supplied

Lug intervals which can be produced on site by rotating the connection lugs

Fixing materials:

• M12 × .-8.8 bolts

(not supplied as standard)

• Lock washers to DIN 6796-12-FSt (2 off per bolt)• Muttern M12-8 nuts

1) Reference dimensions for engineering = centre of AS 3 = centre of lug L 2. 2) Lug intervals apply to cable copper busbar widths ≤ 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

AS transformer and distribution board connection pieces

External dimensions

LD.-AS 3 +LD-.F (+LD-.H)

Lug intervals as supplied

Lug intervals which can be produced on site by rotating the connection lugs

Fixing materials:

• M12 × .-8.8 bolts

(not supplied as standard)

• Lock washers to DIN 6796-12-FSt (2 off per bolt)• Muttern M12-8 nuts

1) Reference dimensions for engineering = centre of AS 3 = centre of lug L 2 (715 mm). 2) Lug intervals apply to cable copper busbar widths ≤ 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

AS transformer and distribution board connection pieces

External dimensions

LD.-AS 4 +LD-.A(C)

Lug intervals as supplied

Lug intervals which can be produced on site by rotating the connection lugs

Fixing materials:

• M12 × .-8.8 bolts

(not supplied as standard) • Lock washers to DIN 6796-12-FSt (2 off per bolt)

• Muttern M12-8 nuts

1) Reference dimensions for engineering = centre of lug L 3 (L 1)2) Lug intervals apply to cable copper busbar widths ≤ 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

AS transformer and distribution board connection pieces

External dimensions

LD.-AS 4 +LD-.B(D)

Lug intervals as supplied

Lug intervals which can be produced on site by rotating the connection lugs

Fixing materials:

• M12 × .-8.8 bolts

(not supplied as standard)

• Lock washers to DIN 6796-12-FSt (2 off per bolt)• Muttern M12-8 nuts

1) Reference dimensions for engineering = centre of lug L 3 (L 1)2) Lug intervals apply to cable copper busbar widths ≤ 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

AS transformer and distribution board connection pieces

Connection lugs

Connection lugs for AS 1 to AS 4

� PEN(N) connection lug

View ZLDA 3.-AS. +LD-.

LDC 3.-AS. +LD-.

LDA 6(7).-AS. +LD-.

LDC 7.1.-AS. +LD-.

LDC 7.2.-AS. +LD-.

LDA 8.1.-AS. +LD-.

LDA 8.2.-AS. +LD-.

LDC 8.1.-AS. +LD-.

LDC 8.2.-AS. +LD-.

with half PEN(N)-conductor

with full PEN(N)-conducter, all lugs are identical

� PEN(N) = ½ L for LDA 6(7).1. and

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

AS transformer and distribution board connection pieces

Connection lugs

Connection lugs for AS 1 to AS 4

Connection lugs, Type VI for AS 3 and AS 4

Customized connection lugs

1) Elongated holes with centre spacing of 55 mm to provide:

50 mm spacing for connection of braided cable, width of 100 mm, 60 mm spacing for connection of braided cable, width of 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

AS transformer and distribution board connection pieces

Connection lugs

PE connection lugs for AS 1 to AS 4

LD.6.-AS. +LD-1.

LD.6.-AS. +LD-2.

Basic lugs of the LD connection feeder unit

1) Elongated holes with centre spacing of 55 mm to provide:

50 mm spacing for connection of braided cable, width of 100 mm, 60 mm spacing for connection of braided cable, width of 120 mm.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

AS transformer and distribution board connection pieces

Flange plate

Aluminium flange plate and enclosure cutout

� Centreline of LD.-AS = cutout centreline

Type suffix

Phase sequence,

Offset

LD.3.-AS 1

LDA 6(7,8).-AS 1

LDC 6.-AS 1

LDC 7(8).-AS 1

LD.3.-AS 2

4 × 213.75 = 855

LDA 6(7,8).-AS 2

LDC 6.-AS 2

LDC 7(8).-AS 2

LD.3.-AS 3

LDA 6(7,8).-AS 3

LDC 6.-AS 3

LDC 7(8).-AS 3

LD.3.-AS 4

8 × 212.5 = 1700

LDA 6(7,8).-AS 4

LDC 6.-AS 4

LDC 7(8).-AS 4

LD.3.-AS 4

8 × 212.5 = 1700

LDA 6(7,8).-AS 4

LDC 6.-AS 4

LDC 7(8).-AS 4

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Cable connection units

Cable entry plate for single-core cable (+LD-BPAL)

Enclosure Cable entries

(see

dimension b)

LDA 1.2.-KE. 1

LDA 2.2.-KE. 1

LDA 3.2.-KE. 2

LDA 4.1.-KE. 2

LDA 4.2.-KE. 2

LDC 2.2.-KE. 2

LDA 5.1.-KE. 3

LDA 5.2.-KE. 3

LDC 3.2.-KE. 3

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

VE, VEU distribution board connection units

Connection to SIVACON 8PV and 8PT power distribution systems

The figures show the most important dimensional details using selected examples.

-LH angular connection units

-LHL-Z* offset connection units

LD. 1 – 3 = 360LD. 4 – 8 = 420

LD. 1 – 3 = 360

LD. 4 – 8 = 420

500 . 1240 LD. 1 – 3 = 360

LD. 4 – 8 = 420

500 . 1240 500 . 1240 LD. 1 – 3 = 360

LD. 4 – 8 = 420

LD. 1 – 3 = 360 . 1300LD. 4 – 8 = 420 . 1300

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

VE, VEU distribution board connection units

Connection to non-Siemens power distribution systems (FA 1) and incoming cable connection units (KE)

The figures show the most important dimensional details using selected examples.

-VEH angular connection units

LDA (C).-VE.

-VEHL offset connection units

LDA (C).-VE.

LD. 1 – 3 = 360LD. 4 – 8 = 420

LD. 1 – 3 = 360

LD. 4 – 8 = 420

LD. 1 – 3 = 360 . 1300LD. 4 – 8 = 420 . 1300

LD-VEG 1(2) (-5) distribution board connection flange

LD-VEG 1 (-5)

LD-VEG 2 (-5)

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Connection units for non-Siemens distribution boards

4-pole

LDA 2420-FA 1

1) For the length of connection lugs see table on the following page.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Connection units for non-Siemens distribution boards

Dimensions of FA 1, 4-pole

Conductor material: Aluminium

Connection

LDA 2420-FA 1

LDA 3420-FA 1

LDA 5410-FA 1

LDA 7410-FA 1

LDA 8410-FA 1

LDA 5420-FA 1

LDA 7420-FA 1

LDA 8420-FA 1

Conductor material: Copper

Connection

LDC 2420-FA 1

LDC 3420-FA 1

LDC 6410-FA 1

LDC 7410-FA 1

LDC 8410-FA 1

LDC 6420-FA 1

LDC 7420-FA 1

LDC 8420-FA 1

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Connection units for non-Siemens distribution boards

Enclosure cutout details for connecting a 4-conductor LD system

LDA 2420-FA 1

LDC 2420-FA 1

LDA 3420-FA 1

LDC 3420-FA 1

LDA 5410-FA 1

LDC 6410-FA 1

LDA 7410-FA 1

LDC 7410-FA 1

LDA 8410-FA 1

LDC 8410-FA 1

LDA 5420-FA 1

LDC 6420-FA 1

LDA 7420-FA 1

LDC 7420-FA 1

LDA 8420-FA 1

LDC 8420-FA 1

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Connection units for non-Siemens distribution boards

5-pole

LDA 2620-FA 1

1) For the length of connection lugs see table on the following page.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Connection units for non-Siemens distribution boards

Dimensions of FA 1, 5-pole

Conductor material: Aluminium

Connection

LDA 2620-FA 1

LDA 3620-FA 1

LDA 5610-FA 1

LDA 7610-FA 1

LDA 8610-FA 1

LDA 5620-FA 1

LDA 7620-FA 1

LDA 8620-FA 1

Conductor material: Copper

Connection

LDC 2620-FA 1

LDC 3620-FA 1

LDC 6610-FA 1

LDC 7610-FA 1

LDC 6620-FA 1

LDC 7620-FA 1

LDC 8620-FA 1

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Connection units for non-Siemens distribution boards

Enclosure cutout details for connecting a 5-conductor LD system

LDA 2620-FA 1

LDC 2620-FA 1

LDA 3620-FA 1

LDC 3620-FA 1

LDA 5610-FA 1

LDC 6610-FA 1

LDA 7610-FA 1

LDC 7610-FA 1

LDA 8610-FA 1

LDC 8610-FA 1

LDA 5620-FA 1

LDC 6620-FA 1

LDA 7620-FA 1

LDC 7620-FA 1

LDA 8620-FA 1

LDC 8620-FA 1

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Connection units for non-Siemens distribution boards

Braided cable busbar connection

Recommended cross-sections of braided cable busbars

Conductor material: Aluminium

Connection

LDA 2420-FA 1

LDA 2620-FA 1

LDA 3420-FA 1

LDA 3620-FA 1

LDA 5410-FA 1

LDA 5420-FA 1

LDA 5610-FA 1

LDA 5620-FA 1

LDA 7410-FA 1

LDA 7420-FA 1

LDA 7610-FA 1

LDA 7620-FA 1

LDA 8410-FA 1

LDA 8420-FA 1

LDA 8610-FA 1

LDA 8620-FA 1

Conductor material: Copper

LDC 2420-FA 1

LDC 2620-FA 1

LDC 3420-FA 1

LDC 3620-FA 1

LDC 6410-FA 1

LDC 6420-FA 1

LDC 6610-FA 1

LDC 6620-FA 1

LDC 7410-FA 1

LDC 7420-FA 1

LDC 7610-FA 1

LDC 7620-FA 1

LDC 8410-FA 1

LDC 8420-FA 1

LDC 8610-FA 1

LDC 8620-FA 1

1) For dimension h see FA 1 dimension tables

(4-pole and 5-pole)

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Connection units for non-Siemens distribution boards

Mounting information for connections

M10 × 40M = 45 Nm

The fixing materials illustrated here are included in the scope of supply.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Tap-off units

Tap-off units with GSTA fuse switch-disconnectors, Degree of protection IP 30

Without cabling box (end cable entry)

With cabling box (side cable entry)

3 Tap-off unit fitted

Space requirement for fitting (IP 30)

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Tap-off units with GSTA fuse switch-disconnectors, Degree of protection, Schutzart IP 54

Without cabling box (end cable entry)

With cabling box (side cable entry)

Tap-off unit fitted

Space requirement for fitting (IP 54)

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Tap-off units

Tap-off units with GSTZ fuse switch-disconnectors

Tap-off unit with door

Tap-off unit without door

The external size of the coding brackets can be found in the dimension table for trunking units with tap-off points.

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Tap-off units with NZM 7 circuit-breaker (80 . 250 A)

LD-K.AK./LSH-.-.

Tap-off unit fitted

Space requirement for fitting

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Tap-off units

Tap-off units with NZM 10 circuit-breaker (400 . 570 A)

LD-K.AK./LSH-.-.

Tap-off unit fitted

Space requirement for fitting

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Tap-off units with NZM 14 circuit-breaker (800 A)

LD-K.AK./LSH-.-.

Space requirement for fitting

Space requirement for fitting

Tap-off unit fitted

Tap-off unit fitted

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Accessories

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Suspension bracket for horizontal suspension

LD-B 1

Fixing bracket for vertical fixing

LD-BV

LDA 1 to LDA 3

LDC 2 to LDC 3

LDA 4 to LDA 8

LDC 6 to LDC 8

� LD system� Front� To be supplied on site

� For 80 Nm� Socket, 22 mm� Extension� Ratchet, two-directional� Knee joint

Siemens LV 71 · 2004/2005

LD Busbar Trunking System

Dimension Drawings

Notes

Siemens LV 71 · 2004/2005

A&D Online services

Alphabetical and type reference index

Condtions of sale and delivery,

export regulations

Siemens LV 71 · 2004/2005

In accordance with IEC/EN 60439-1, rated values are supplied by the manufactur-

The rated values should be used as a basis for co-ordination of equipment or en-

ers of low-voltage switchgear and controlgear assemblies. These rated values

gineering the switchgear assemblies.

apply for the specified operating conditions and characterise the usability of a switchgear assembly.

(AC) Rating or rated power

The operational power that an equipment is capable of switching at the asso-

IEC/EN 60947-1; 4.3.2.3

ciated rated operational voltage in accordance with the utilization category, e.g. contactor utilization category AC-3: 37 kW at 400 V.

Rated conditional short-circuit current (Icc)

The rated conditional short-circuit current corresponds to the prospective short-

IEC/EN 60439-1; 4.5

circuit current which a circuit of a switchgear assembly can carry when protected by a short-circuit protective device, without sustaining damage (for a specified duration). For this reason the rated conditional short-circuit current is quoted for tap-offs and/or feeder units with circuit-breakers, for example.

Rated conditional short-circuit current

a Rated conditional short-circuit current (Iq)

IEC/EN 60947-1; 2.5.29

Rated control circuit-voltage (Uc)

Voltage which is supplied to the actuating make contact in a control circuit. Due

IEC/EN 60947-1; 4.5.1

to the presence in the control circuit of transformers or resistors, this voltage may differ from the rated control supply voltage.

Rated current In) (of a circuit-breaker)

Current which for circuit-breakers is equal to the uninterrupted current and the

IEC/EN 60947-2; 4.3.2.3

conventional free-air thermal current.

a Rated uninterrupted current

The frequency for which an equipment is designed and to which the other char-

IEC/EN 60947-1; 4.3.3

acteristics are refered.

a Rated uninterrupted current

Rated operational voltage

Rated impulse withstand voltage (Uimp)

Measures the stability of the internal clearances inside a switchgear against

IEC/EN 60947-1; 4.3.1.3

overvoltage peaks. The utilization of suitable switchgear can ensure that over-voltages are prevented from transfering from the mains to deenergized system sections within it.

Rated insulation voltage (Ui)

The voltage to which insulation tests and creepage distances refer. Under no cir-

IEC/EN 60947-1; 4.3.1.2

cumstances is the highest rated operational voltage permitted to exceed the

rated insulation voltage.

a Rated operational voltage

Rated making capacity

The current which a switchgear unit is capable of switching on in accordance

IEC/EN 60947-1; 4.3.5.2

with the utilization category and at the rated operational voltage.

a Rated operational voltage

Rated operational current (Ie)

The current that an equipment is capable of carrying, taking into account the

IEC/EN 60947-1; 4.3.2.3

rated operational voltage, duration of operation, utilization category and ambi-ent temperature.

a Rated operational voltage

Rated operational voltage (Ue)

The voltage to which the characteristics of a switchgear unit are refered. Under

IEC/EN 60947-1; 4.3.1.1

no circumstances is the highest rated operational voltage permitted to exceed the rated insulation voltage.

a Rated insulation voltage

Rated peak short-circuit withstand current (Ipk)

The rated peak withstand current describes as the peak value of the surge cur-

IEC/EN 60439-1; 4.4

rent, the dynamic strength of a circuit in a switchgear assembly. The rated short-time withstand current is generally specified for the distribution system and/or main busbars of a switchgear assembly.

Rated service short-circuit breaking capacity (Ics)

The prospective short-circuit current which, depending on the rated operational

IEC/EN 60947-2; 4.3.5.2.2

voltage, a circuit-breaker is capable of breaking repeatedly (test cycle O–CO–CO, previously P2). After interrupting this short-circuit current value, the circuit-breaker must be capable of continuing to carry and disconnect in the event of overloading, the rated uninterrupted current, despite its own thermal level hav-ing increased. a Rated uninterrupted current

Rated operational voltage

Siemens LV 71 · 2004/2005

Rated short-circuit breaking capacity (Icn)

The maximum value of current which a switchgear unit is capable of switching

IEC/EN 60947-1; 4.3.6.3

off at rated operational voltage and rated frequency without sustaining damage. It is expressed as r.m.s. value. a Rated operational voltage

Rated short-circuit making capacity (Icm)

The maximum value of current which a switchgear unit is capable of switching

IEC/EN 60947-1; 4.3.6.2

on at a specific rated operational voltage and rated frequency without sustaining damage. Unlike other characteristics values, this is expressed as a peak value.

a Rated operational voltage

Rated short-circuit withstand current (Icw)

The rated short-circuit withstand current describes, as the effective value of the

IEC/EN 60439-1; 4.3

short-circuit current, the thermal strength of a circuit in a switchgear assembly during transient loading. The rated short-time withstand current is normally determined for the duration of 1 s, and any divergent times must be stated. The rated short-time withstand current is specified for the distribution system and/or main busbars of a switchgear assembly.

Rated ultimate short-circuit breaking capacity (Icu)

Maximum short-circuit current, which a circuit-breaker is capable of interrupting

IEC/EN 60947-2; 4.3.5.2.1

(test cycle: O–CO, previously P-1). After interrupting this current value the cir-cuit-breaker is capable, with increased tolerances, of disconnecting in the event of overloading.